BEMA fylder 75 år

BEMA nyhedsbrev, april 2022

BEMA FYLDER 75 ÅR

I dette nyhedsbrev vil vi tillade os til at fokusere lidt på os selv. Vi vil ellers helst fortælle om vores kunders succeser, men til maj fylder BEMA A/S 75 år – og det synes vi nok er værd at fortælle om. Og det skal fejres!

I anledning af vores 75-års jubilæum vil vi gerne invitere kunder, leverandører, samarbejdspartnere og venner af huset til reception.

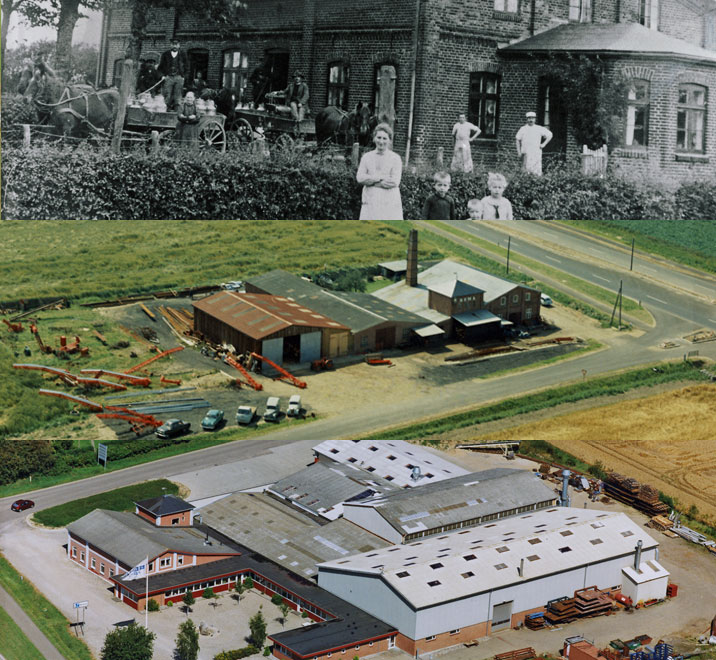

Fra landbrug til kompleks industri

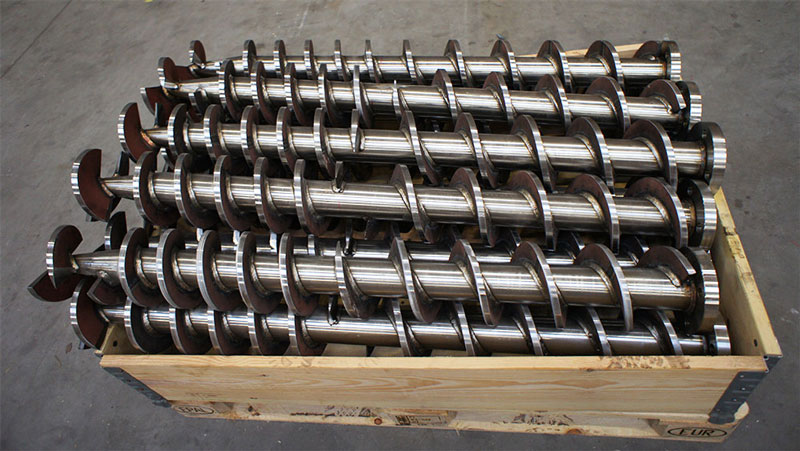

Det hele begyndte i 1947 med transportører til landbruget. De mange landbrug rundt omkring i landet var i fuld gang med at blive moderniseret og mekaniseret i årene efter 2. verdenskrig. Og med den stigende mekanisering opstod der også et stort behov for transportører. BEMA blev hurtigt en betydelig leverandør af den slags udstyr til landbruget, og det endte senere med snegletransportører. I slutningen af april måned vil vi lægge et lille jubilæumsskrift ud på vores hjemmeside, som kan downloades. Her er historien om BEMA fortalt.

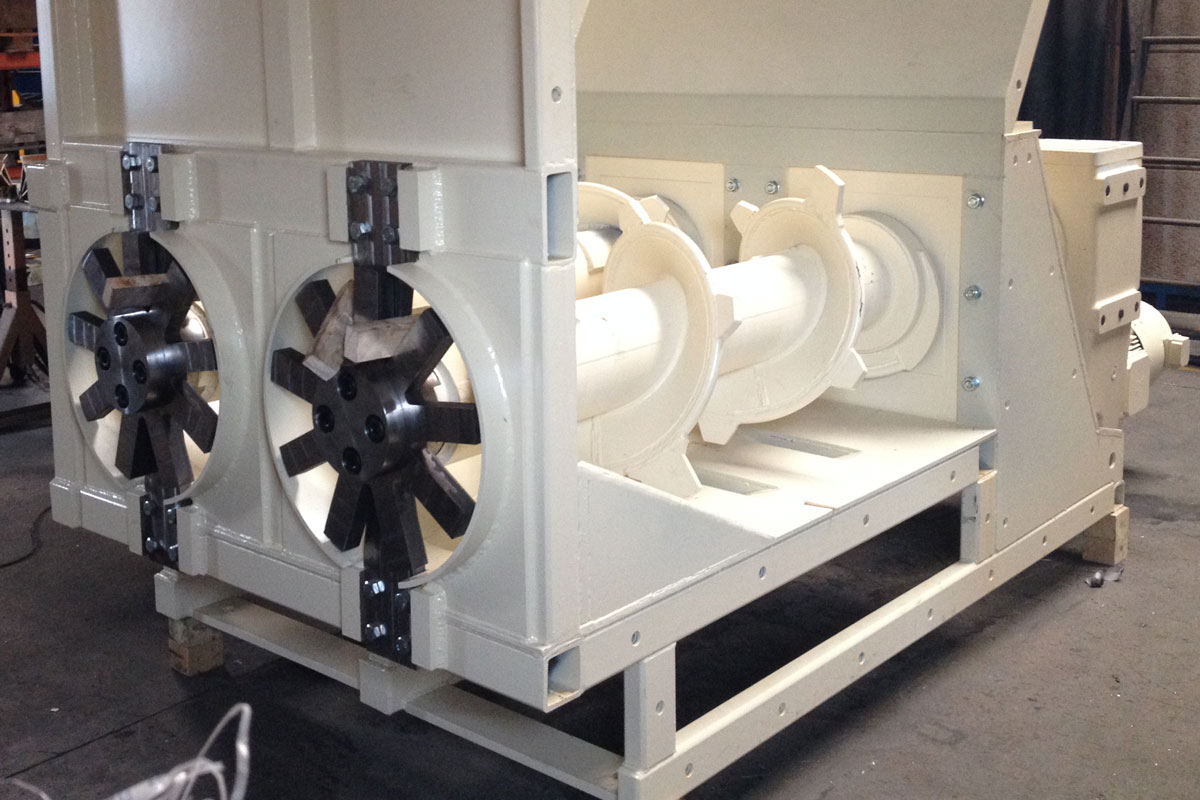

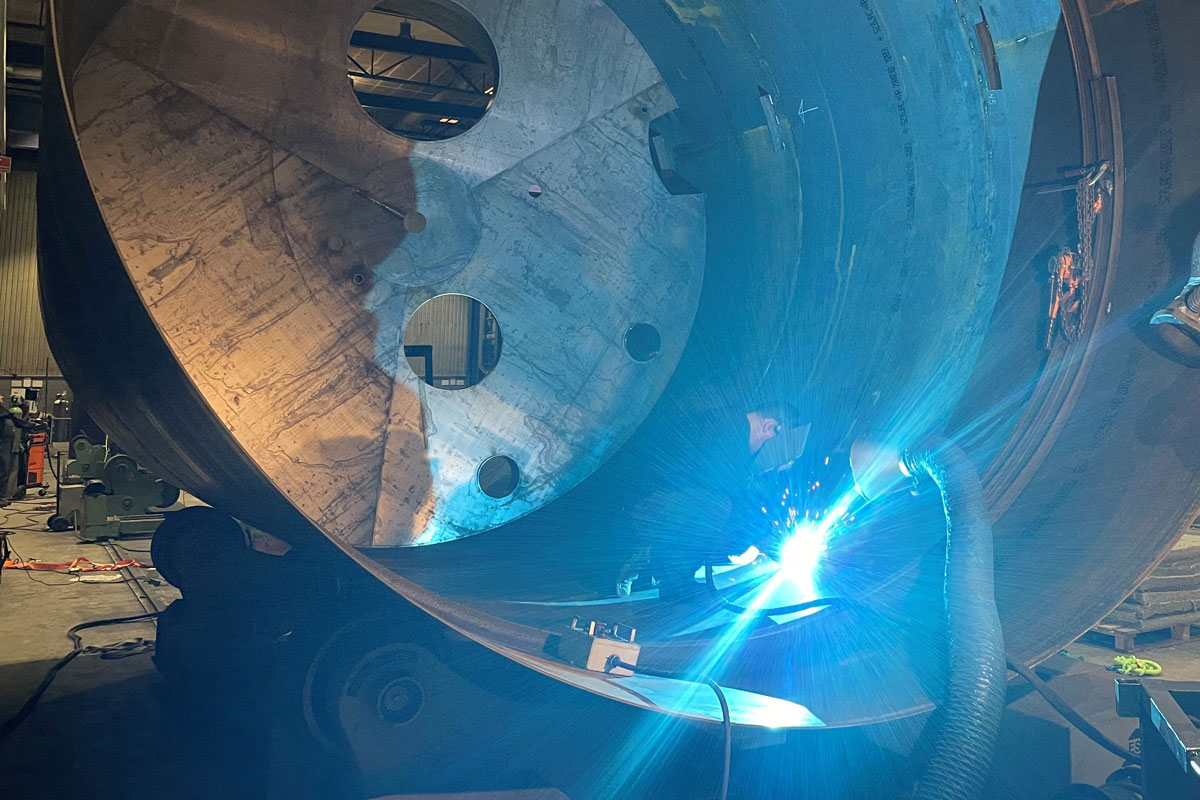

For nogle årtier siden ændrede vi vores strategi: Vi havde udviklet vores kompetencer inden for snegletransport, så vi følte os i stand til at gå ind i mere komplekse løsninger. Det har været en stor succes og givet mange nye muligheder. I dag leverer BEMA til en lang række industrier og forsyningsvirksomheder. Vi er blandt andet godkendt til at producere udstyr til fødevareindustrien og er ISO 9001 certificerede.

BEMA leverer i dag både enkeltkomponenter og samlede, komplekse løsninger.

De senere år har vi også udviklet virksomheden ved at overtage andre. Med købet af Ferreo har vi styrket vores kompetencer inden for procesudstyr i rustfrit stål. Med ACTA har vi taget skridtet ind på markedet for maskiner til neddeling, balleåbning m.v. med udstyr, der bruges i recyclingindustrien, både den private og offentlige.

Al produktion, lager, salg og administration er samlet i vores 6.700 m² store bygninger i Haderslev – tæt på den sønderjyske motorvej. Vi er 65 medarbejdere, og vores udstyr er i drift i store dele af verden.

Det er vigtigt at have et godt fundament, når man udvikler sig. Adm. direktør Jørgen Strøm siger: ”BEMA har en lang historie og har vist, at der er behov for vores produkter og ydelser. Det giver livskraft til en fortsat udvikling af BEMA A/S. Vi er glade for at have jer med på rejsen og ser frem til de næste mange år med fokus på produktudvikling, kvalitet og god service”.

Nyt lys over BEMA A/S

I disse tider er der god grund til at satse på at spare på energien: Alle former for energi stiger, som alle nok har opdaget, helt vildt i pris, og det er ikke en regning, man som produktionsvirksomhed nødvendigvis bare kan sende videre til kunderne. Så må man spare!

Hos BEMA har vi netop udskiftet 500 lysarmaturer med traditionelle lysstoffør. I stedet er der kommet LED-belysning ind, og dermed kan vi reducere elforbruget med mere end 93.000 kWh om året. Da vi lavede beregningerne i sin tid, betød det er besparelse på omkring 200.000 kr. om året – nu er den med de stigende priser endnu større.

Energibesparelser handler ikke kun om kroner og ører. Det er også en gevinst for klima og miljø, når vi bruger mindre el og dermed udleder mindre CO2 og andre skadelige stoffer. Udskiftningen af lysarmaturerne betyder, at vi udleder 1,2 tons CO2 om året.

Det nye LED-lys giver også et langt bedre arbejdslys for medarbejderne. Det er slut med ekstra arkitektlamper på arbejdsbordene i produktionen, og medarbejderne har fået et bedre arbejdsmiljø.

Værkfører Bo Lorenzen siger: ”Flere og flere kunder går også op i, at vi har en miljørigtig profil. Så vi skal tænke ind, hvordan vi i hele produktionsflowet kan indarbejde energibesparelser, mindre ressourceforbrug og andet, så vi lever op til de stigende forventninger, som der er til vores indsats for miljøet”.

Ny hjemmeside gør det nemmere for jer

Her i begyndelsen af april har vi lanceret vores nye hjemmeside www.bema.as. Af og til er der nemlig god grund til en gang oprydning på ens hjemmeside. Vi valgte at begynde helt forfra med nyt design, ny struktur og en mere visuel og intuitiv måde at gøre information om produkter, cases og kontakter tilgængelig på, så det hele bliver nemmere for jer som brugere at gå til.

Samtidig er der bagved kulissen gjort et stort stykke arbejde for at gøre BEMA lettere at finde for folk, der søger på emner, som vi ved noget om. Denne såkaldte SEO-optimering er ikke noget, som brugerne af hjemmesiden ser noget til, men den gør os mere synlig på søgemaskiner som Google. Og det er vigtigt, for som de fleste andre virksomheder oplever vi Jørgen Strøm

også, at mange kontakter og forespørgsler i første runde foregår via internettet.

Kig endelig forbi www.bema.as og se, hvordan den nye side tager sig ud. Er der ting, du mangler eller synes er besværlige, så lad os det vide – så tager vi det med, når vi løbende justerer siden.