BEMA – embracing continuous change

BEMA newsletter, March 2024

BEMA – EMBRACING CONTINUOUS CHANGE

At BEMA, stagnation is not in our vocabulary. We aim to keep evolving and improving. One notable trend in recent years has been the steady increase in the size and complexity of our projects, compared to our basic products. We take pride in the fact that both new and loyal customers choose us when they need solutions designed and produced, whether it is a standalone project or intergraded into larger systems.

In this newsletter, we will share a couple of these larger projects we have been working on.

INVENTORY MANAGEMENT AND SAFETY

To ensure efficient handling of tasks and consistently meet customer demands, we utilize the Stockmaster inventory management system. This system automatically alerts our suppliers and internal production system when inventory levels are low, ensuring that we always have the necessary supplies available. Additionally, Stockmaster will now encompass parts that have worn down in our lathe department, which helps creating a more streamlined production with complete control over all processes.

However, our focus extends beyond inventory management and production efficiency. Ensuring floor safety is equally vital for maintaining a secure workplace and meeting the high standards our customers expect. As part of our commitment to safety, we have participated in a research project focused on workplace health and safety. Following a thorough assessment, we achieved a score of 75 out of 100 points. While this is quite high, we have further improved our score by an impressive +10% throughout the duration of the project.

10-YEAR WORK ANNIVERSARY

Many know our Sales and Product Manager, Ronny Bæk, from meetings, customer visits, and trade fairs. He has just reached a significant milestone at BEMA A/S – his 10-year anniversary, but he thankfully aims for at least ten more. We are thrilled because Ronny is not only highly competent and well-liked but also a key driver in the ongoing development of project sales and custom solutions here at BEMA A/S. We congratulate Ronny on his ten years at BEMA!

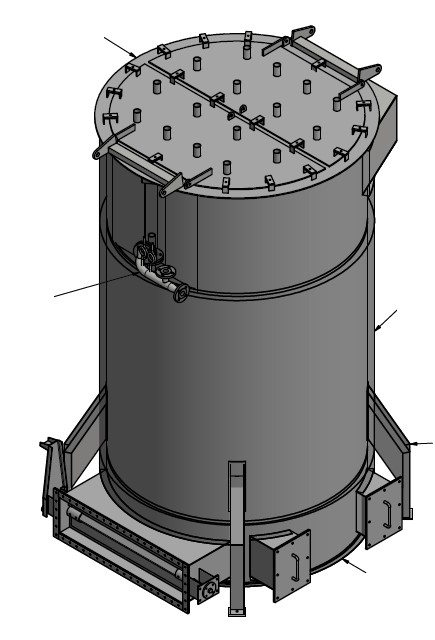

BOILER TO THE INDUSTRY

We have recently completed the production of a large pressure vessel, also known as a boiler, for one of our clients. This boiler will serve as the core component in a larger project solution. While the client provided the boiler design, we at BEMA A/S have handled the complete manufacturing process in accordance with all specifications and test requirements.

A crucial aspect of this project was third-party testing of welds and pressure equipment. Non-Destructive Testing (NDT) was conducted on all welds, and Pressure Equipment Directive (PED) tests were performed on the boiler’s pressure equipment. External certification serves as an additional assurance for the client, confirming that the work has been carried out to meet all requirements and specifications in the field. We went the extra mile by testing the boiler up to 24 bars, surpassing the minimum requirement of 18 bars.

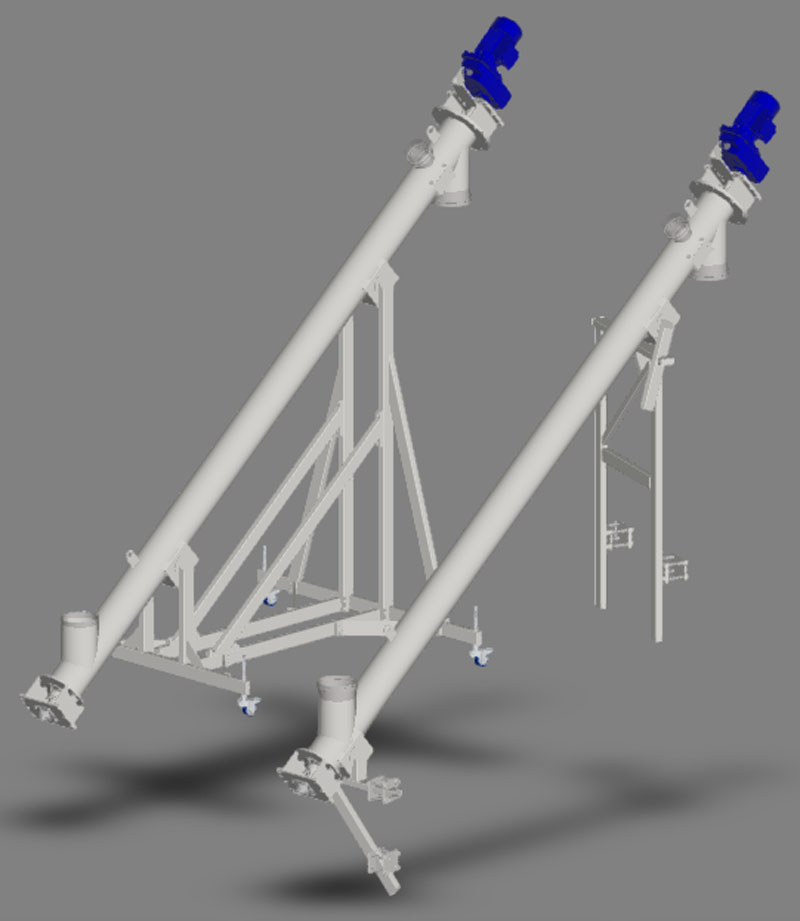

COMPREHENSIVE TRANSPORTATION SCREW CONVEYOR SOLUTIONS TAILORED FOR THE ENERGY SECTOR

For one of our clients abroad in the energy sector, we have produced no less than 14 conveyors with a diameter of 500 mm and 2 conveyors with a diameter of 600 mm. They are part of a large system for biogas production. The transportation screw conveyors vary in length – the shortest being 6,000 mm and the longest 13,600 mm. These conveyors transport the residual product from the biogas production across multiple levels to a final storage with six silos. From here, the farmer can retrieve the residual product, which is used as fertiliser.

The complete transportation screw system is designed to go around several pillars, along different floor levels, a staircase and in connection with walking decks, among other places. The system is divided into two parts, each with three storage silos, where our transportation also includes mixing screws, ensuring that the residual product is similar and can be immediately returned to the fields as fertiliser.

It has been a demanding design task, but the result is 16 custom-made screw conveyors that can be easily installed on site.

SCREW FLIGHTS DELIVERED TO THE OTHER SIDE OF THE WORLD

We have delivered screw flights to the other side of the world – 8975 km away, to be exact. Distance is not an obstacle for us, since we have recently dispatched a series of individually tailored crafted screw flight conveyors to a client in Honduras. This addition further enriches our already substantial international clientele.

The screw flights have been crafted from Hardox 450 and stainless steel 1.4301/AISI-304 and made with cut offs on the outer diameter. This requires a special design, showcasing our ability to tackle any winding challenge — even when the client is located on the opposite side of the globe.

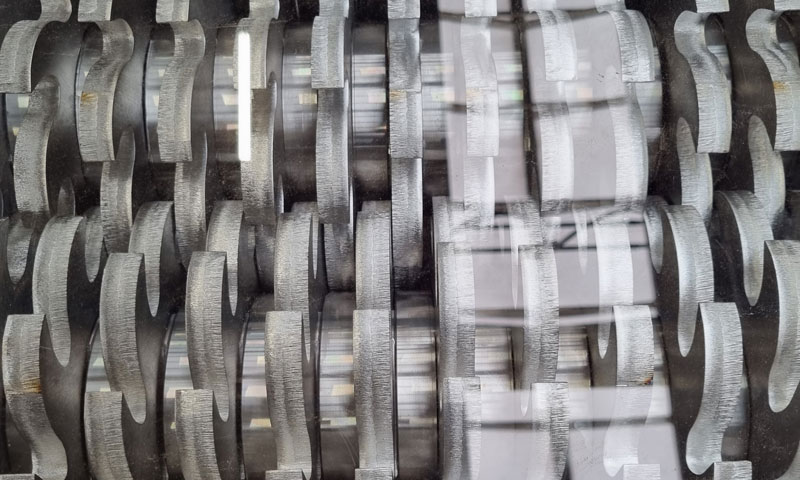

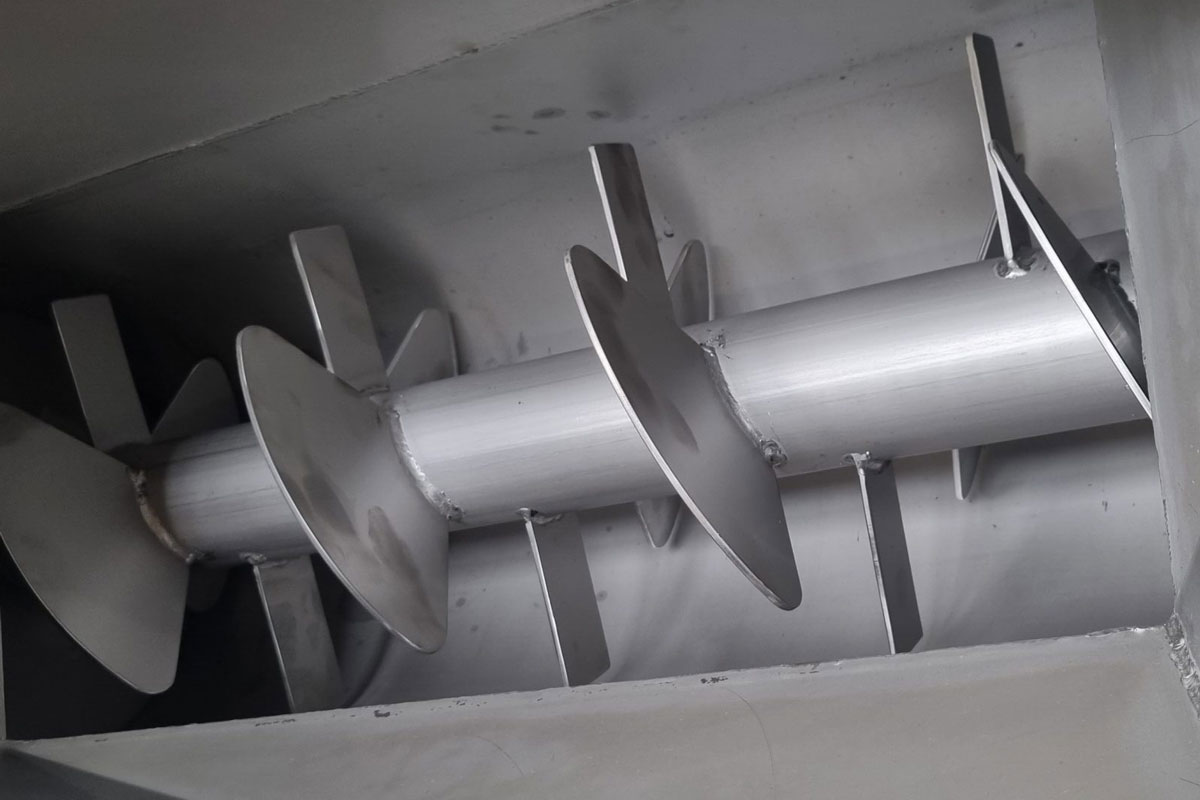

In any BEMA transport solution, the most crucial component is the screw flights. For a screw rotor to fulfill its purpose, endure many hours of work, and require minimal maintenance, then the screw flight has to be precisely and perfectly crafted.

We have extensive experience in producing screw flights, covering all aspects from dimensioning to calculating pitch, thickness, inner diameter, and outer measurements. Our screw flights are manufactured through cold pressing, which guarantees optimal durability and strength. Even though it may sound simple, trust us, it is not that simple!

Our engineering department specialises in designing custom screw flights of any configuration, which gets tailored to fit the specific screw rotor. Precise screw flights save countless hours of adjustments during fabrication—and reduces costs! Therefore, we continuously strive to enhance our screw flight production to ensure they seamlessly fit when welded onto the core tube.

One of our specialties includes large screw flights measuring up to approximately a diameter of 2500 mm in Hardox and other abrasion resistant steel types. Here, we utilise sandwich plates that meet the demands of particularly abrasive applications. However, we also cater to smaller requirements if that is what you desire!