BEMA newsletter, May 2020

News from BEMA

We’re here for you – also during these unusual times

The last couple of months have presented us all with a completely new agenda. Regardless of our function in society, everyone has experienced how their everyday lives have been turned upside down because of a new coronavirus, the Covid 19.

However, BEMA continues its work, undaunted by the corona crisis and, so far, we have managed to serve all our customers as usual. We’re here for you – also during these unusual times! We are ready to solve tasks for you and we are able, for example, to offer our customers assembly as part of the total conveyor project. Perhaps the new framework set by these corona times will generate new opportunities for collaboration if we work together with a constructive attitude.

As of January 2020, and since the last newsletter, ACTA Recycling has merged with BEMA and is now a full member of the BEMA Group.

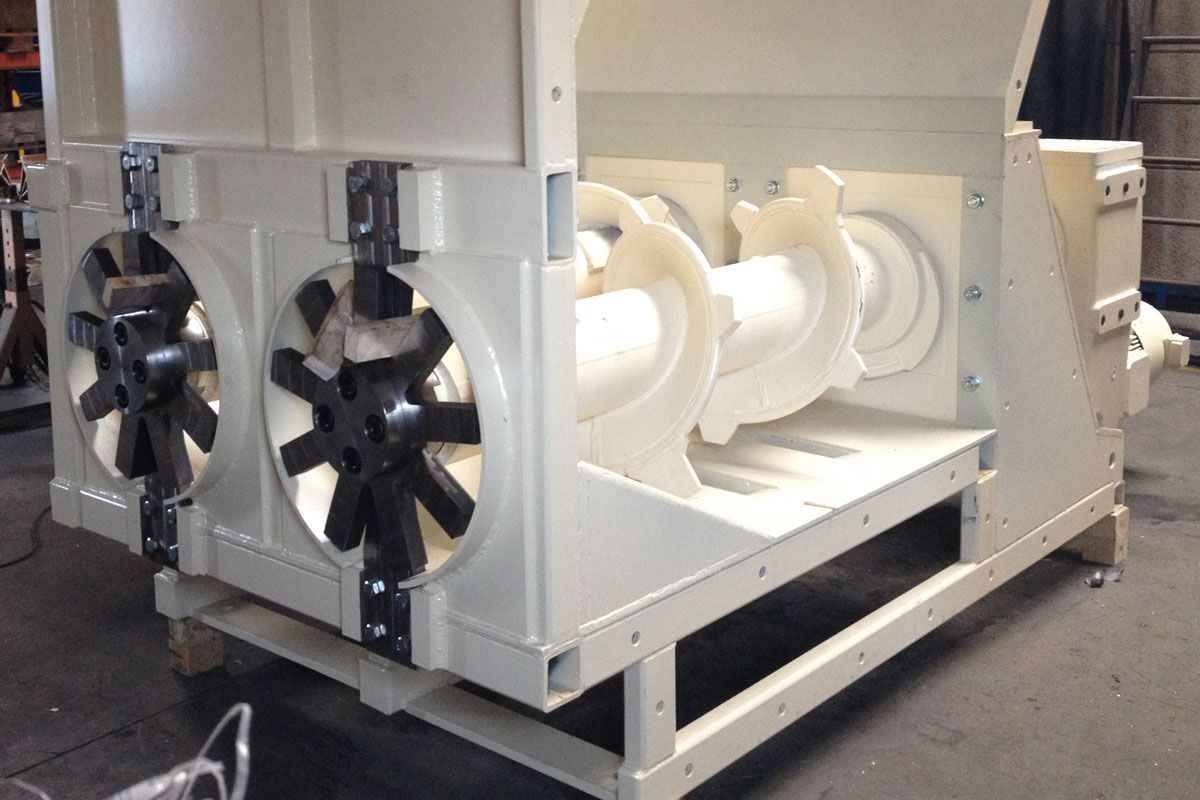

ACTA crusher ready for shipment

ACTA supplies crushers used for a number of purposes: crushing various materials such as wood and plaster before processing it further for recovery, also PET bottles, etc. The machine is a key component in the value chains where waste is upcycled into new products. The ACTA crusher is the first step on the way.

Here, a six-screw ACTA crusher is being assembled ready for shipment. This is a total shipment where we are responsible for the construction of the machine and for structuring the accompanying control system.

The recycling industry is a growing business area and our expectations are high at BEMA. Still, BEMA works across a wide spectrum in all industries. In our stainless-steel workshop, we solve tasks for the food and processing industry where we experience a growing activity. BEMA strives to become a provider of the basic value chain and we are able to provide conveyors suited to all sectors.

Components – solutions matching all your needs

Components are an important part of BEMA’s production. Component parts for specific solutions which customers may need to reorder and replace due to wear and tear.

Accordingly, we produce all types of screw conveyors. They are customised to heavy industry as well as to the food industry where an extremely high finish is required in order to comply with the strict hygienic requirements applicable in this industry.

We produce both ordinary steel and stainlesssteel screw conveyors. Each one is allocated a unique article number, which means that we can quickly produce them again when required.

All types of flights

We also produce flights of all types – cylindrical as well as more complex conical flights or notched and cut flights. A speciality of ours are large-scale flights of up to approx. 2500 mm in diameter in Hardox and other wear-resistant steel types. Here, we are working with composite panels which meet the requirements of high-wear applications.

We know that accurate flights reduce the time spent on welding the screw conveyor. Our construction department can thus construct flights in any shape adapted to a given conveyor screw. Accurate flights save many hours of adaptation in the workshop during production – thus reducing the cost! Consequently, we work hard to optimise our production of flights so that they are a perfect fit when welded to the core barrel.

BEMA has an extensive range of standard flights. Our dedicated technicians and production staff are ready to produce precisely the flights you need for your system.

Contact us for enquiries about:

- Stainless steel process equipment

- Screw conveyor systems

- Conveyor screws

- Screw flights

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as