BEMA newsletter, September 2020

News from BEMA

We look forward to meeting you again!

This spring and summer could be characterised as a hundred-year event: very uncommon and not something one wishes to see happening again in the immediate future. COVID-19 has shut down society for long periods.

Although we, at BEMA, have been working for the whole period and have solved tasks for our clients as usual, much has nevertheless changed from what we’re used to. We now work with a greater physical distance and we have become used to working via video links just like you. Actually, arranging meetings with customers, suppliers, and others via Teams has been a positive experience. Perhaps something good will come of that, for example, less travel time for short meetings.

Normally, the autumn would be packed with trade fairs. Sadly, everything has been cancelled this year – we will miss the pleasure of your company and our technical discussions at the fairs. But we are ready to meet you online or in real life. Let’s have a chat about projects and products!

Forty-six metres of screw conveyor for drilling mud on offshore installation

With this assignment, BEMA has been offshore and solved this special task in connection with upgrading an existing drilling rig. Despite being in deep water out there, we were able to solve a complete and complex production assignment where we have to adapt to very special conditions.

The offshore environment is extreme and a screw conveyor measuring no less than forty-six metres put tough demands on both construction and materials as well as production quality.

Our task involved specifying a correct design for the long screw conveyor, producing it, and testing it in the presence of the end user. In addition to this, we provided ATEX approval with risk assessment and a full documentation package.

The conveyor house is made of acid-resistant stainless steel and a number of special designs facilitate adapting it to the actual installation environment. For example, the conveyor has special manually operated locks for the gratings, facilitating removal for maintenance.

Prior to delivery, the solution has undergone thorough testing at a fullscale test set-up at the BEMA factory in Haderslev.

Tanks for all industrial sectors

We are increasingly supplying tanks to various industrial sectors. Especially the food industry, for which we have the special approvals required, so that we can be a provider for this sector with its specific requirements relative to hygiene and materials.

Tanks are often part of integral solutions where we provide the total solution including conveyor systems, tanks, process components, and installation.

Contact our sales department for an informal chat about how we can solve your tank requirements.

Components – also for abrasives

Over the years, BEMA has gained extensive knowledge about producing flights of all types and we experience a growing interest in flights suitable for abrasives. This could e.g. be the transportation of ash in combined heat and power stations (CHPs), but also many other types of abrasive materials.

Learn more about our component programme in wear-resistant steel and hard-alloy coating. We are experts in the renovation of screw conveyors with hard-alloy coating and the replacement of wear parts, enabling us to maintain and upgrade your conveyor system.

Contact our sales department for further information.

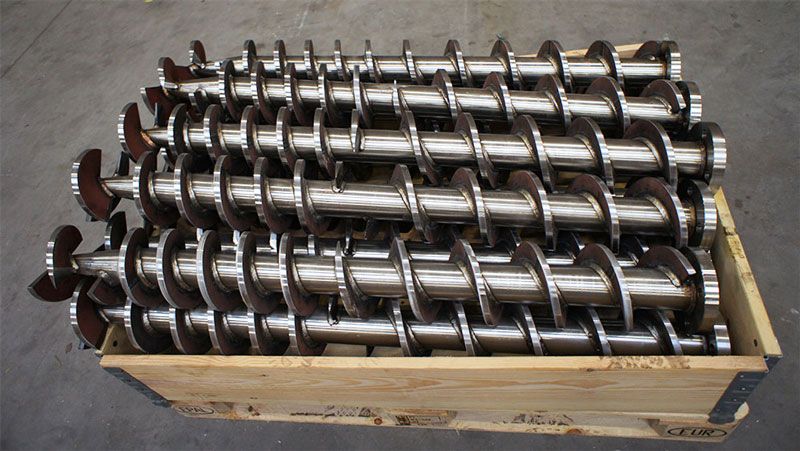

Serial production of screw conveyors

Machine manufacturers using screw conveyors in their product series often need uniform components to satisfy their requirements and needs. We subscribe to this kind of OEM production (original equipment manufacturer) and have acquired sufficient capacity to produce screw conveyors matching the serial sizes and specifications required.

To learn more, contact our sales department.

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as