Trough screw conveyors for slag – 20447

Trough screw conveyors for slag – 20447

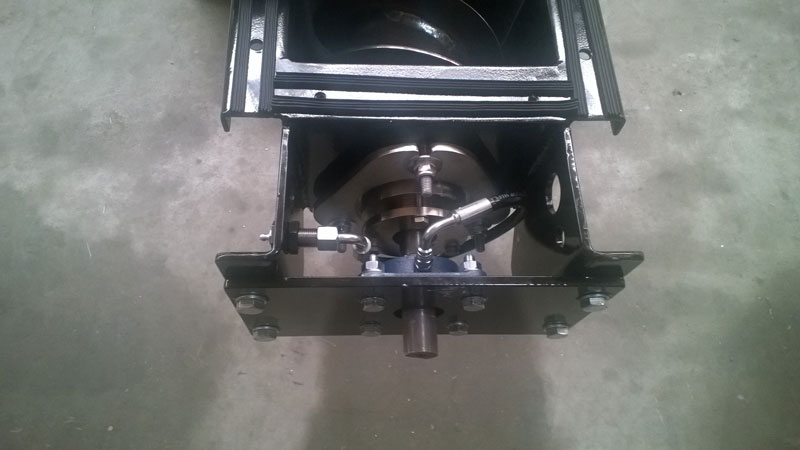

Through screw conveyors for slag delivered to a straw fired power plant. The screw conveyors are replacing existing screw conveyors where intermediate bearings are used.

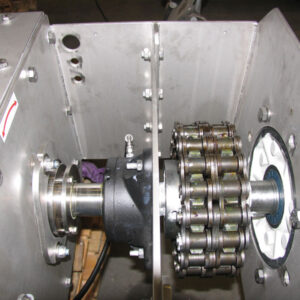

Why shall you avoid intermediate bearings in screw conveyors for slag and ash?

- The ash from the transport will no matter how distribute into the intermediate bearing

- After a very short time the intermediate bearing will break down caused by the abrasive material

- No matter how low you decrease the filling degree of the through screw conveyor, intermediate bearings shall be avoided

Through screw conveyors are very suitable for transporting ash coming from the boiler process in a powerplant.

What are the advantages for using trough screw conveyors?

- The screw conveyor only have one moving part – the screw rotor

- The bearings are sitting outside of the machine and have no contact with the material

- If the ash is highly abrasive you can you Hardox steel to reduce the wear on the screw flights

- You can keep the material completely closed in a trough screw conveyor

See another example of screw conveyors for ash transport

Key factors to consider when you design screw conveyors for slag and ash

- The filling degree shall be low – app. 10%

- If possible keep the inclication of the trough screw conveyors below 15°

- If the inclination exceeds 15° consider to use Hardox steel for the screw flights

- Always use bolted lids to ensure tightness of the screw conveyors towards the exterial environment

When you order through screw conveyors in BEMA we always offer to supply all relevant components such as:

- Supporting cribs

- Legs for carrying the screw conveyors

- Inlet and outlets for easy adaptation during installation

- Chutes and other relevant equipment

BEMA’s design department with our own engineers and technicians have many years of experience to design complete solutions. The additional components can save you valuable installation time and cost for your screw conveyors.

Trough screw conveyors for slag – 20447

- Diameter: Ø200

- Length: 4000-6000 mm.

- Material: All manufactured in carbon steel. Painted outside to a customer defined color

- All screw augers are self supported – no hanger bearings are used

- Flange bearings moved away from the house to avoid dust from the screws

- Adjustable shaft seals with packing cords to ensure tightness

- Supplied with rotational guard

- Supplied with lids, supports and connections for easy installation

| Product type | Screw conveyor |

|---|---|

| Industry | Power plants |

| Transported material | Ash |

| Applied steel in product | Carbon steel, Hardox plate |

| Surface treatment | Carbon steel – painted |

Related solutions

Related products

-

Horizontal screw conveyor for ash – 7047

Read more -

Ash screw conveyor for humidifying – 21413

Read more -

Inclined tube conveyors for ash transport – 27436

Read more -

Trough screw conveyors for ash – 18850

Read more -

Ash screw conveyors for high temperature – 18582

Read more -

Auger with paddles for ash and slags – 34619

Read more

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as