Ash screw conveyors for high temperature – 18582

18582

Ash screw conveyors for high temperature – 18582

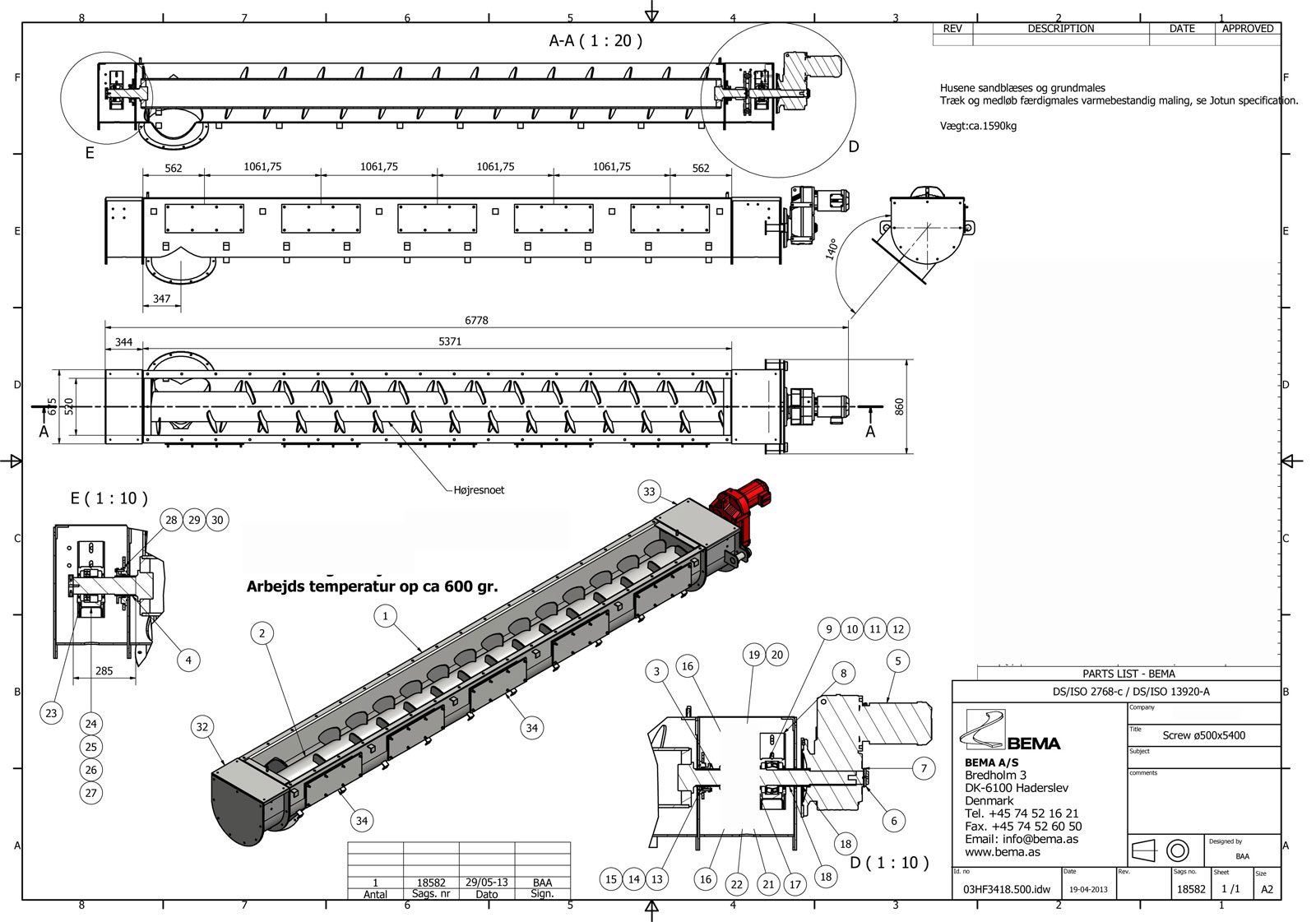

Ash screw conveyors for high temperatures manufactured to sit below two owens and deliver ash to pneumatic transportation system. The ash screw conveyors are designed to resist temperature up to 600 °C. A project of 5 ash screw conveyors are designed, manufactured and delivered to a waste incineration plant.

What is the specific design parameters in the plant?

- Temperature up to 600 °C

- The screw conveyors must operate 24 hours a day with only one revision during the year

- 2 conveyors sit directly under the boiler and receive ash and slags from the process and during air-blasts

Key design features of the ash screw conveyors

- Housings manufactured in boiler steel. The boiler steel is perfect to resist the specified temperature

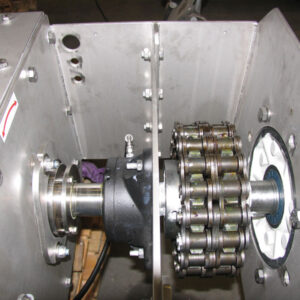

- Separation of the drive shaft and the screw rotor by using a special coupling with low heat transfer capability

- The screw rotors under the boiler are manufactured with paddle design to be able to handle ash and slag lumps

- The screw converyors are supplied with inspection plates in the body for the possibility to come in and clean the screw rotors

- The material of the screw rotors are 253-MA heat resistant stainless steel

- Ensured a low filling degree to ensure a long lifetime of the ash screw conveyors

See another ash screw conveyor for handling high temperature ash

This project is an example of BEMA’s capability to handle screw conveyors for high temperature ash. In this project BEMA has:

- Designed the screw conveyors

- Made a complete set of manufacturing drawings

- Manufactured the screw conveyors

- Assembled and tested them in our workshop

- Performed a FAT together with the customer

- Delivered the screw conveyors on-site

Ash screw conveyors for high temperature – 18582

- Length: 5000-7000 mm.

- Diamter: Ø500

- Material:

- Screw conveyor housing: Boiler steel

- Screw flights: MA-253 heat resistant stainless steel

- Screw flights under the boiler with paddle design for ability to break lumps

- Screw rotors designed to be able to move 35 mm. in axial direction due to the high temperature

- Surface treatment: Heat resistant silicon paint system

- A special coupling between the drive shaft and the screw rotor to reduce heat transfer

- Heavy industrial design of the screw conveyors to resist temperatures up to 600 °C

Related solutions

Related products

-

Ash screw conveyor for humidifying – 21413

Read more -

Inclined tube conveyors for ash transport – 27436

Read more -

Screw conveyor classifier for unburned slag – 36593

Read more -

Trough screw conveyors for ash – 18850

Read more -

Screw coneyor for ash transport with built in water tank – 24371

Read more -

Horizontal screw conveyor for ash – 7047

Read more

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as