Cooling tubular screw conveyor – 9023

Cooling tubular screw conveyor – 9023

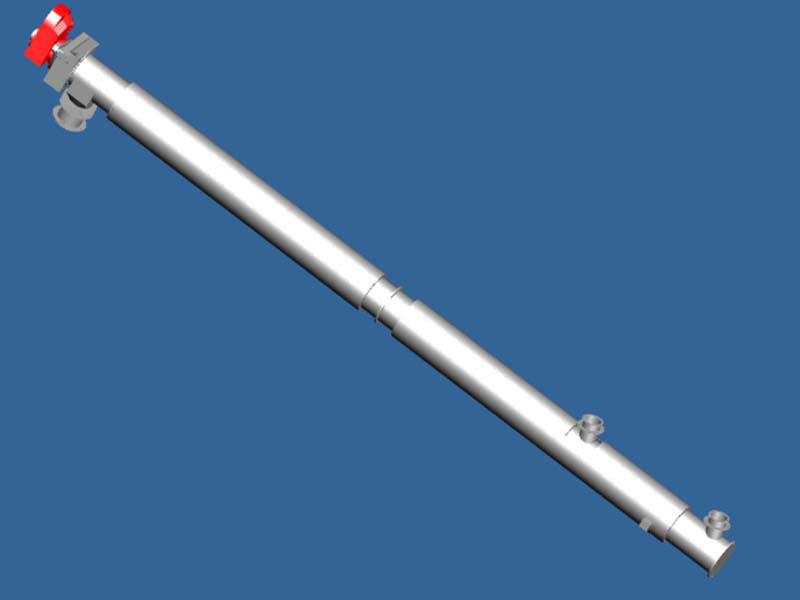

Tubular cooling screw conveyor Ø400×9985 mm. for cooling residual product in the process industry. The screw conveyor has only jacket cooling easily implemented by welding 2 tubes with different diameter together.

What to consider if you only want to implement jacket cooling in a cooling screw conveyor

- The filling in the screw conveyor must be as high as possible. A high filling degerees ensures good contact with the cooling zone

- Lower the speed of gear box to increase the residence time in the screw conveyor

Jacket cooling is more economical in comparison with cooling of screw flights by using the hollow screw flight principle. The method has to be evaluated to the demands there is for cooling of the material.

Key points when designing a cooling screw conveyor with jacket cooling

- Start to calculate the needed surfarce. You can consider the cooling screw conveyor as a standard parallel heat exchanger.

- In this process estimate the overall heat transfer coefficient. This coefficient strongly depends on customer experience with the material.

- design the cooling jacket and justify that it is possible to cool the material with this metod only

In this actual BEMA has manufactured a complete support system for the cooling screw conveyor. When delivered on-site it is ready for insallation and connection of cooling water. The cooling screw conveyor is installed inclined on the site. The material is lifted during the cooling process. This makes it more difficult to control the cooling process, but it is possible if the material is easy to transport in a screw conveyor.

See a similar application for a cooling screw conveyor by using the hollow flight principle

In BEMA we have experience with design and manufacturing of cooling screw conveyors.

Different types of cooling methods in cooling screw conveyors

- Jacket cooling

- Cooling of the screw flights by using the hollow flight principle

- Cooling of the inner tube of the screw rotor

- A combination of the 3 types above

BEMA can assist you in the design and planning phase. Our engineers and designers have many years of experience working with cooling screw conveyors.

Cooling tubular screw conveyor – 9023

- Material:

- Housing and cooling jacket manufactured in carbon steel

- Screw flights manufactured in Hardox-450 steel

- Length: App. 9985 mm.

- Diameter: Ø400

- Manufactured including supports and piping for water cooling

- Painted according to customer specifications

- Packed in a wooden frame and shipped directly from BEMA to the end customer

| Product type | Screw conveyor |

|---|---|

| Industry | Offshore |

| Transported material | Bulk material |

| Applied steel in product | Carbon steel, Hardox plate |

| Surface treatment | Carbon steel – painted, Carbon steel – untreated |

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as