Bin discharger with double extraction screws – 24450

Bin discharger with double extraction screws – 24450

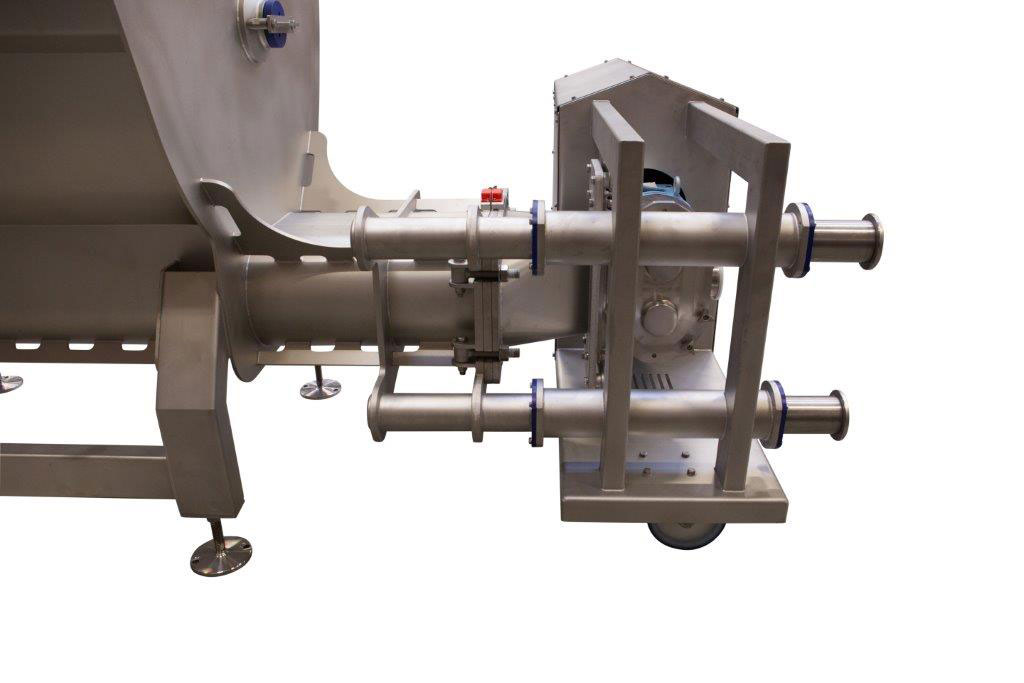

Bin discharger with double extraction screws designed and manufactured in accordance with EC-1935/2004 (the food directive).

The bin is manufactured with a mixing screw rotor inside the bin.

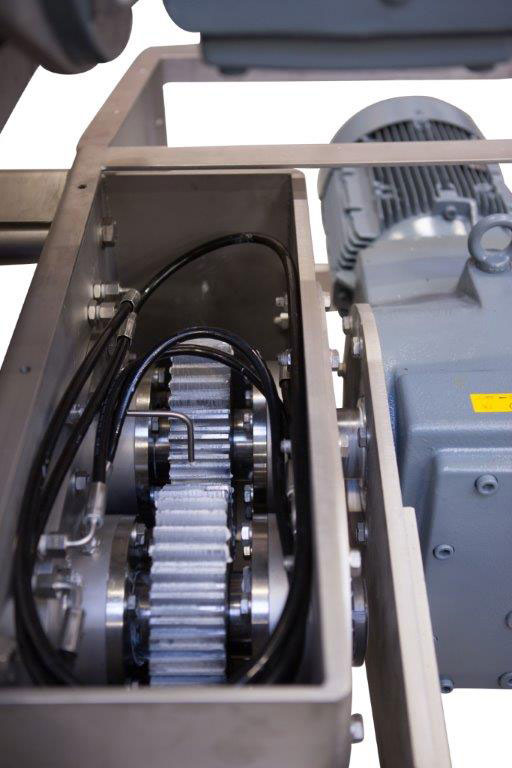

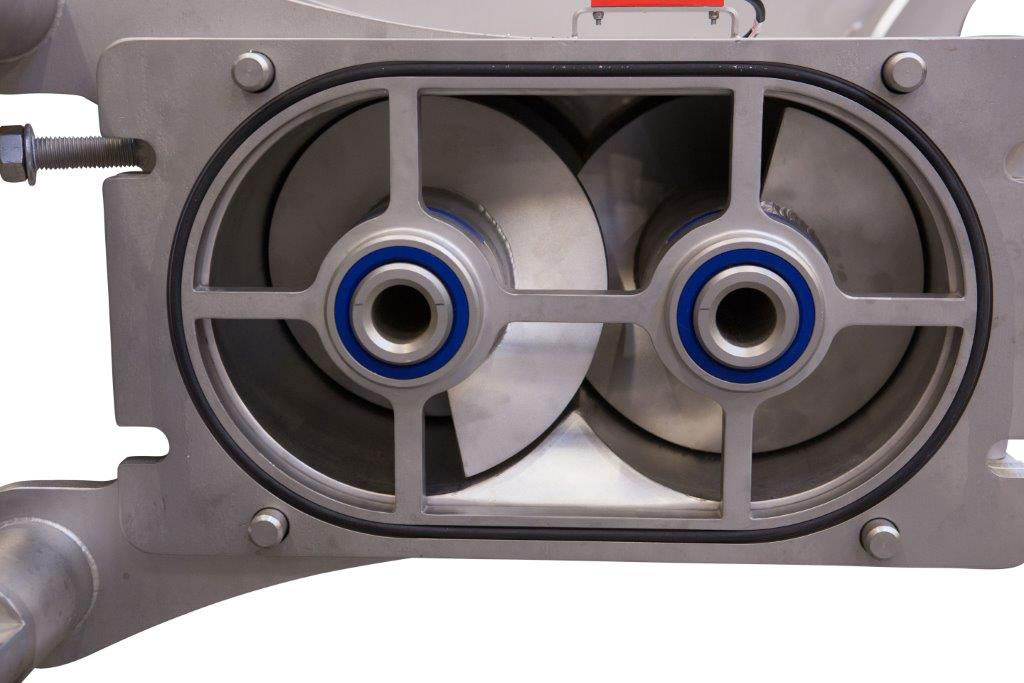

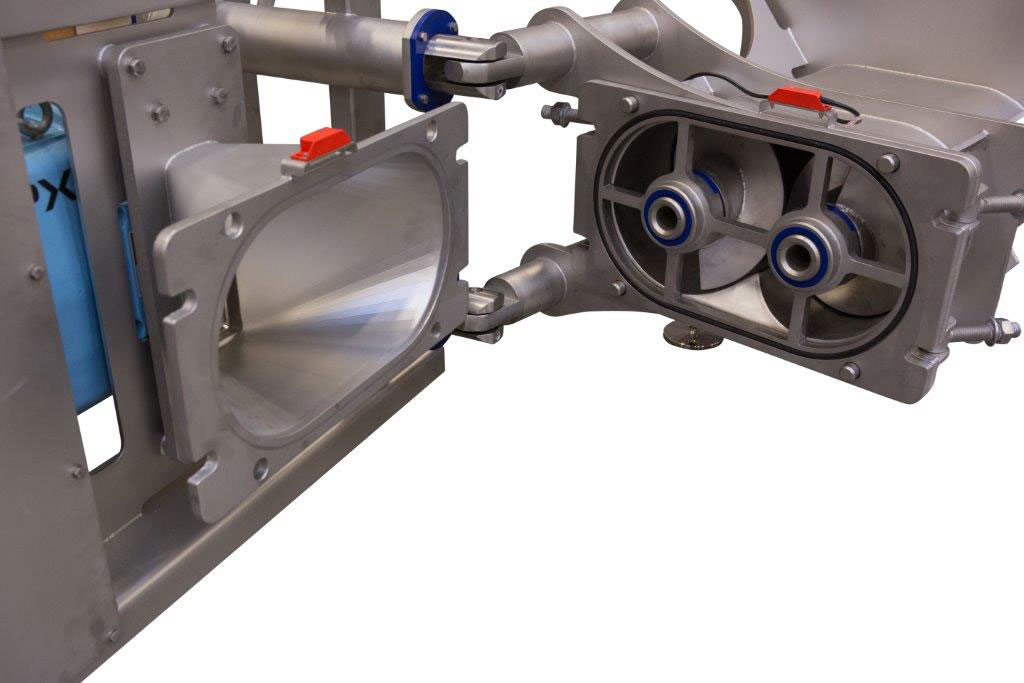

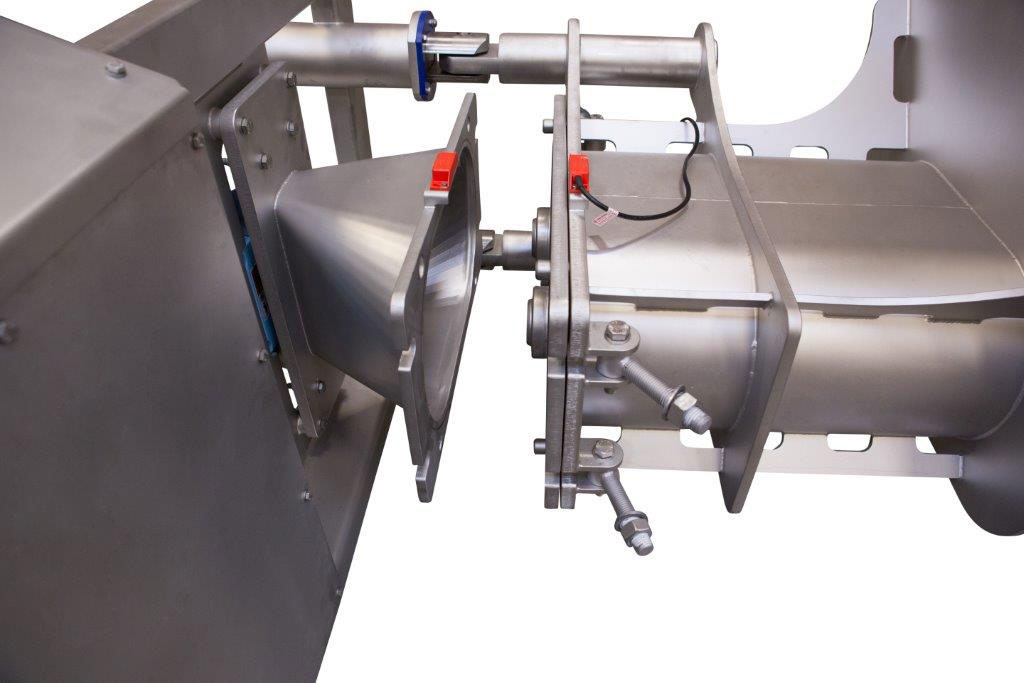

The double extraction screws delivers the material to a screw pump. The extractions screws are separated via a gear box that ensures that they run in intersection.

The bin combines the following functions

- Storage

- Mixing

- Transport/extraction to a pump

The complete solution is delivered on a frame including a wheel station for the pumping part.

The design has taken hygienic issues into consideration. Whereever possible horizontal surfaces are avoided to ensure that cleaning water can easily drain off.

BEMA has over the years gained experience in designing applications for the food industry. It requires skilled engineering capabilities to ensure workable hygienic designs of screws for food applications.

Issues to consider when designing a bin with a screw conveyor for the food industry

- Ensure that it is as easy to clean as possible

- Define the level of surface treatment of steel in contact with the material

- Ensure that all material in contact with the food is in accordance with EC-1935/2004

- Define the level of documentation you want for your application

BEMA has a design department that can assist you in selecting the right level for your application. Always keep in mind that surface treatment is expensive and can become more and more expensive when you increase your demands. We recoomend you to be critical from the beginning for the design with respect to surface treatment. Hygienic surfaces is not only a discussion of small Ra values. In most of the cases 2B colled rolled plates, TIG welding and acid pickling is enough.

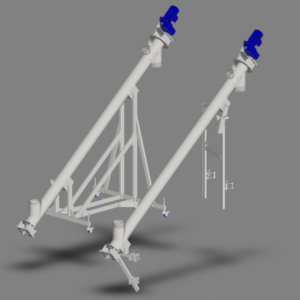

See similar examples of screw conveyors for food application

Bin discharger with double extraction screws – 24450

- Material: Manufactured in 1.4301/AISI-304

- Surface treatment: Grinded on the internal surface to Ra 0,6, acid pickled and glass blasted on outside surfaces

- Outer diameter of double screws: Ø275

- Diameter of mixing screw: Ø985

- Designed to be cleanable on outside surfaces – the gear box is covered with steel plates

- The machine is manufactured to be a process machine for food ingredients

- BEMA has designed the complete solution in cooperation with the customer

| Product type | Process equipment, Screw conveyor |

|---|---|

| Industry | Food industry |

| Transported material | Bulk material, Meat |

| Applied steel in product | Stainless steel |

| Surface treatment | Stainless steel – acid pickled, Stainless steel – grinded |

Related solutions

Related products

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as