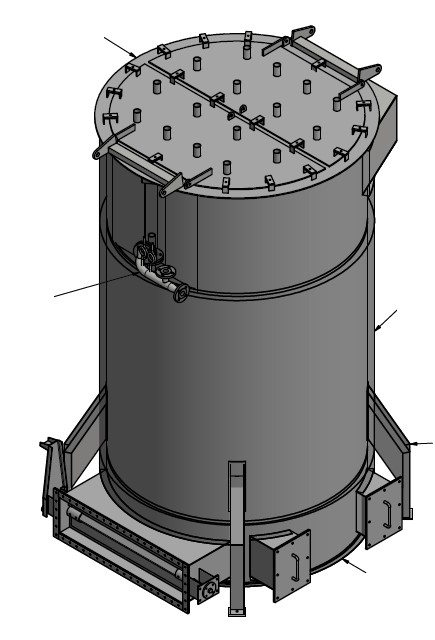

Steam boiler Ø2015 mm – 36007

-

Steam boiler Ø2015 mm – 36007

- Manufactured in boiler steel

- Painted and insulated after welding

During the manufacturing process BEMA has made NDT of the weldings according to customer specification.

BEMA has performed pressure testing together with notified body to ensure compliance with the PED directive.

BEMA has handled the complete manufacturing process in cooperation with the end customer. All design has been made by the customer. BEMA has manufactured the device in accordance with all specifications and test requirements.

The manufacturing of this product is a cooperation between the customer and BEMA, where BEMA acts as a workshop with competent employees who are able to ensure that rules and regulations for the product is obeyed. BEMA has the capability to overview the manufacturing process and ensure that 3’rd part control is applied on the right time.

-

Steam boiler Ø2015 mm

Material: Mainly manufactured from boiler steel P265

Welded by using our own WPS with our own WPQR behind.

Notified body has participated in the pressure testing according to the demands in the PED directive to ensure that the steam boiler is meeting the requirements.

The steam boiler is insulated and afterwards covered with metal sheets in stainless steel 1.4301. Insulation of the steam boiler has been made by an external company which is a specialist in insulation of industrial components.

To sum up – BEMA has performed the following tasks:

- Made detail drawings for the work shop of the steam boiler

- Welded and assembled the steam boiler

- Conducted NDT test in cooperation with a notified body

- Conducted pressure test with a notified body to comply with the PED directive

- Assisted the customer with documentation of the steam boiler in order to get the product finally approved in accordance with the PED directive

-

Applied steel in product Carbon steel

Industry Process industry

Product type Process equipment

Surface treatment Carbon steel – painted, Carbon steel – untreated

Related solutions

Related products

-

33956 Test system for food ingredients

Read more -

28609 Standard evaporator

Read more -

Cyclone separator in stainless steel – 35823

Read more -

32245 170 m3 silo for powder ingredients

Read more -

28932 Condenser unit

Read more -

34333 – Stainless steel soaking tank, for rice boiling

Read more -

32535 Sand and Calcium silo tanks

Read more

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as