On the road again…

BEMA newsletter, September 2023

ON THE ROAD AGAIN…

Autumn is travel time in our industry. We’re attending a number of trade fairs around the world – and soon you’ll be able to meet the team from BEMA at HI-Messen – the large industrial fair in Herning from 3 – 5 October. If you’re attending the Elmia Subcontractor fair in Sweden, we’ll see you there. It takes place from 14 – 16 November. And finally, we are attending Ajour in Odense on 23 – 24 November.

We look forward to welcoming all new and existing customers.

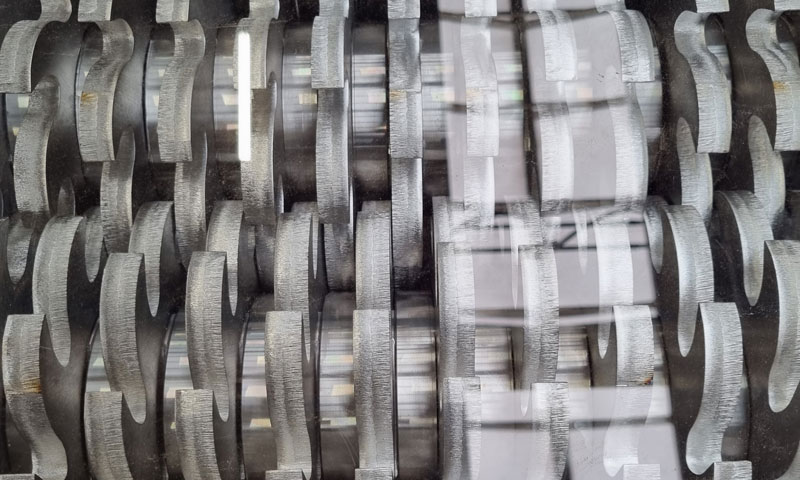

Come and see our crusher / multi-shredder BMN 3000, which will be available in 1:1 scale on our stand. It is a product that we are gradually manufacturing to process e.g. fishing waste, general food products, soap products, chemical products, plastic and paper waste and much more.

Meet us at:

- HI-Messen, Herning, 3 – 5 October, stand no.: J7201

- Elmia Subcontractor, Jönköping, 14-16 November, stand no.: B 06:93

- Ajour, Odense Congress Center, 23 -24 November.

STAINLESS PIPE CONVEYORS WITH ATEX APPROVAL

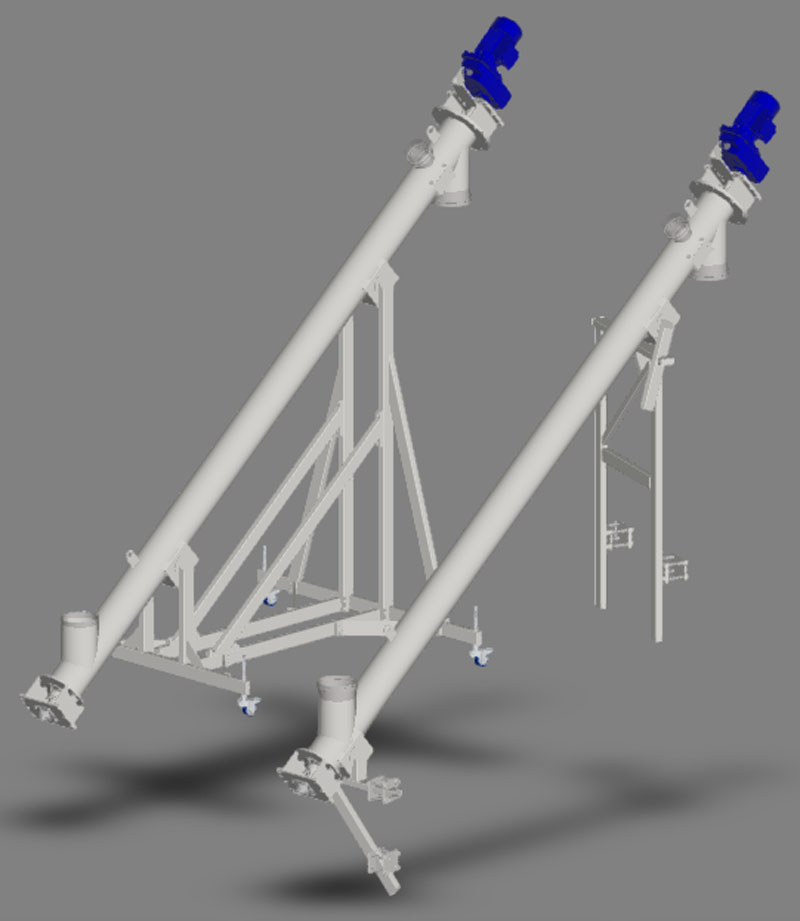

We have just delivered two stainless pipe conveyors to a major ATEX-approved processing plant installed in South Africa. The plant is certified in category ATEX 21, which is the second highest category.

BEMA has extensive experience of producing ATEX-certified equipment that is installed where there is a risk of internal or external explosions. This could be if the recycling process develops or processes gases, or dust or other things that may accumulate and cause overheating and thus an explosion.

The screw rotors are designed to be self-supporting, and they are dimensioned so that they are extra protected against breakage. The equipment also comes with various additional features – such as a rotation guard, which supports safety should a fault occur on the motor or rotor.

We are experiencing an increasing demand for equipment for ATEX-certified systems. The demand is coming from a wide range of industries spanning food and pharmaceutical industries to recycling and raw materials.

CUSTOMER-SPECIFIC CONVEYOR SOLUTIONS

BEMA has made a wide range of conveyor solutions over the years. Close cooperation with our customers ensures that we deliver solutions that are based on a standardised conveyor product but are also carefully adapted to the individual customer’s needs.

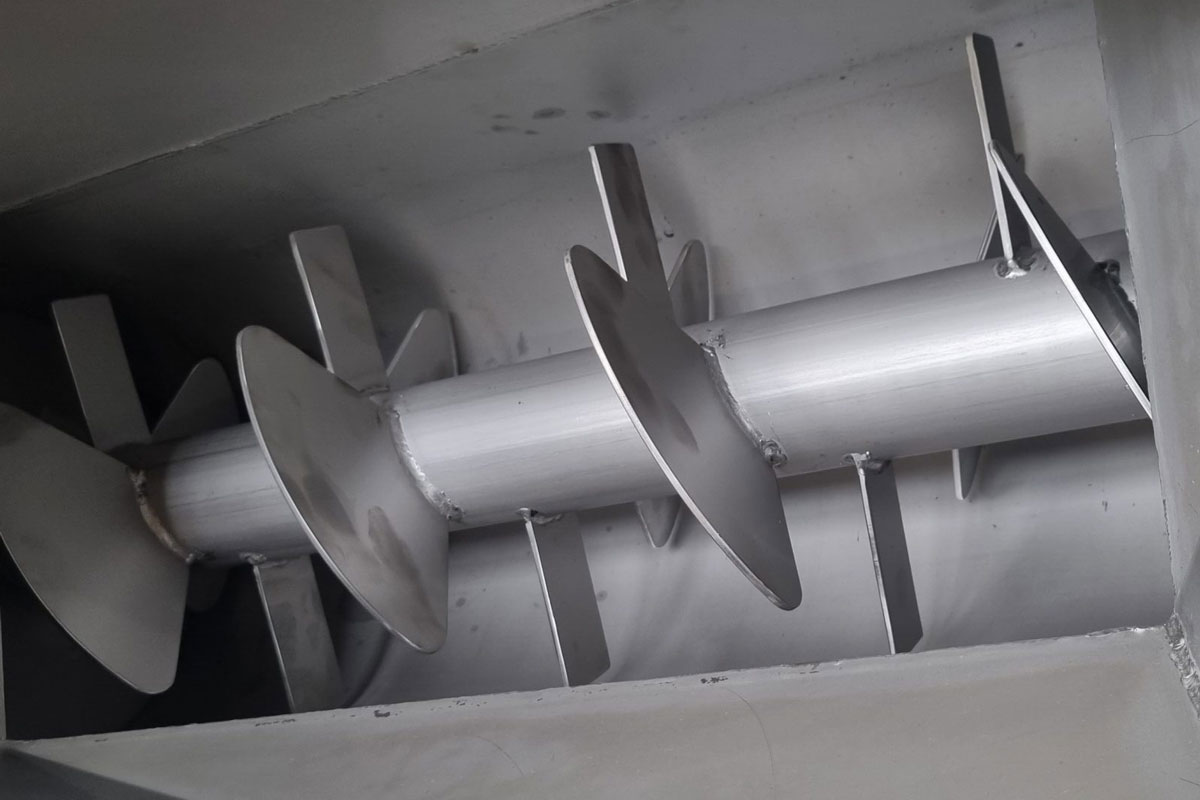

A good example is these four stainless conveyor rotors, which we have equipped with a specially adapted inlet, so that they are optimised for the customer’s overall system.

When the material is loaded down through the special inlet, it ends up in the first part of the rotors, which are equipped with special screw flights to break down the material. For the material’s onward transport, the conveyors are equipped with standard flights to make the transport as efficient as possible.

Read more at www.bema.as under solution no. 35155 and see how we design solutions for customer-specific applications.

FRENCH RECYCLING PROJECT USING BEMA SILOS AND SCREW CONVEYORS

It’s not only in Denmark that we’re sorting waste and trying to secure resources for recycling. Recycling is a global project that will help reduce our consumption of virgin materials from the earth, so that we look after the environment and climate as best as possible. We recently delivered silos with associated screw conveyors to a recycling project in France.

Our products are part of a larger process plant that will be used to sort and clean cable waste. During the process, the cables are separated into their component parts such as plastic, rubber and copper. Copper is a particularly valuable resource that it is important to collect and recycle.

BEMA’s contribution to the facility consists of two silos of 3 m3 each and associated single and double screw conveyors. The first silo contains dry and unsorted cable waste, which the conveyor moves onto a sorting table. From here the waste moves on to silo number two, where it is washed before continuing into the processing plant. As this part of the process is wet, the silo and conveyor installed after the first sorting phase are made of 1.4301/AISI 304 stainless steel. The silo in which the cable waste is washed is designed so that the water can be cleaned and reused. Dirt and debris sink to the bottom, after which it is removed by the conveyor.

See details and photos at bema.as, solution no. 34508.

CAREER AT BEMA?

Things are going well for us and have been for some time. So we are always looking for talented employees who want to use their skills with us and develop a career through the many different jobs we have to offer.

The www.bema.as website has a special section about the exciting career opportunities with us, so take a look and see if we have any jobs that match your profile. We are looking for both skilled and unskilled employees (only in Danish).

If you don’t find a specific job match, then send us an unsolicited application – new needs arise all the time, and we are always hiring.

SCREW FLIGHTS – BEMA’S SPECIALTY

At BEMA, we have no less than 75 years of experience in the manufacture of all types of screw flights. It is a field that requires knowledge, a sense of quality and great care in production.

Our construction department manufactures special flights, which are made to fit the given screw rotor. The precision of our flights will save many hours of workshop adjustment during manufacture, thereby reducing costs!

That is why we are constantly working to improve our manufacture of screw flights – to ensure an optimal fit when they are welded to the core housing.

One of our specialties is large flights of up to approx. Ø2500 in Hardox and other types of hardened steel. These are sandwich panels, able to meet the requirements of particularly abrasive applications. And at the other end of the spectrum we sell small flights, designed to solve specific tasks.