BEMA newsletter, June 2023

SUNNY WEATHER – ALSO ON THE ROOF

Summer vacation is approaching, but BEMA is still going strong. We just launched another exciting initiative – solar panels on the roofs of our production halls! Once they have been fully installed in mid-June, they will be able to cover our entire energy consumption when the season is right. This is yet another step along the green path we want to follow.

There are several advantages to producing our own electricity:

- We will emit less CO2

- Strengthening of our overall environmental profile

- We will become less sensitive to fluctuations in the electricity price

Furthermore, we expect that in the coming years, there will be increasing demands for industrial companies to establish green energy solutions. As a preparatory measure, it makes sense to utilize the space already at our disposal. This also makes the overall solution relatively cost-neutral over a period of five to seven years. All this is a benefit to us as well as our customers.

The solar panels are another element in our efforts concerning energy and the green transition. Previously, we replaced all our light fixtures with LED lighting, both in production and administration. This alone resulted in a significant decrease in our power consumption.

We also believe that the green transition should look good and be seen in our everyday life. It is not just about energy and savings. That is why we have planted 60 fruit trees and 70 fruit bushes in front of the administration building. Hopefully, they will attract bees and other insects, providing food for wild birds. Our employees can also get an extra dose of vitamins by grabbing an apple or a handful of berries during their lunch break. And lastly, we are sowing a variety of wildflower seeds along the production halls, which will contribute to increased biodiversity. It will also be a pretty sight, instead of the usual grass.

TROUGH CONVEYOR WITH SPECIAL SIDEWALLS

We have manufactured a special trough conveyor for one of our customers with special sidewalls that fit perfectly into their process plant.

As the trough conveyor is meant to transport abrasive materials, it was made of stainless steel EN1.4401 combined with 1.4462 duplex steel. The same applies to the housing, ensuring the most durable and cost-effective solution with minimal maintenance required.

The trough conveyor is yet another example of how, at BEMA, we work with our customers to develop solutions that combine design and manufacturing in the best possible way.

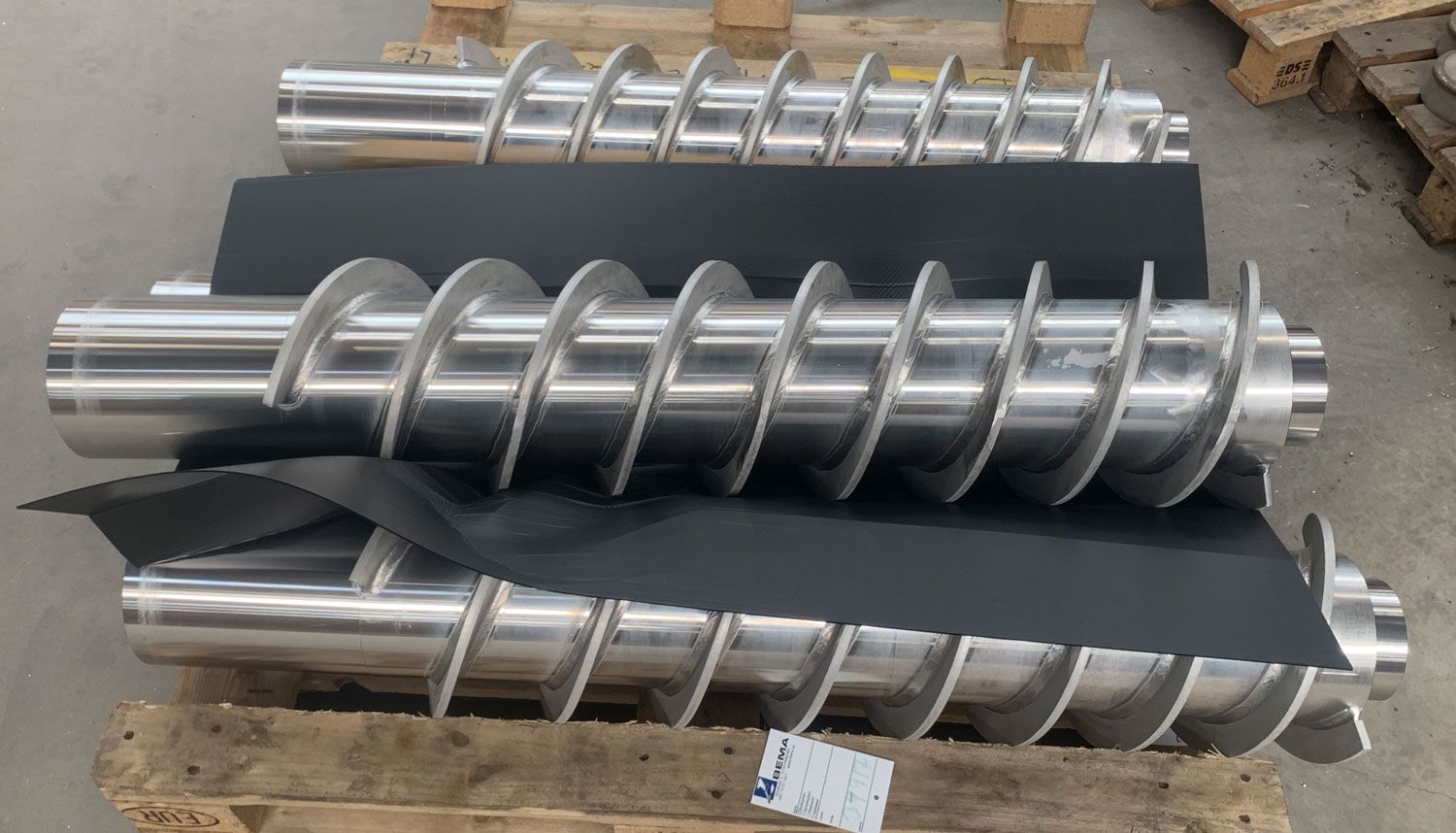

FRAMEWORK AGREEMENT FOR THE SERIES PRODUCTION OF HIGH-END SCREW ROTORS

We have entered into an agreement with one of our customers for the series production of a large number of high-end screw rotors in stainless steel. This is a great example of how we develop projects together with our customers and tailor our production accordingly. As a result, there is a high demand for consistency and precision with these screw rotors. We have established a complete production setup for the task, including specific and precise measuring equipment to ensure high quality throughout.

The screw rotors are manufactured in stainless steel, EN1.4301, AISI-304, and are designed with double threads, requiring precise manufacturing of the screw flights.

Here at BEMA, we have 75 years of experience in the manufacture of screw flights and rotors, and we know the meaning of accuracy and precision when it comes to dimensions, pitch, thickness, inner diameter and overall measurements. We are the market leader of screw rotors for any purpose.

We are happy to take on specialized tasks because our expertise and long experience set us apart from other manufacturers.

Our setup for this particular customer is a prime example of our agile approach to customer projects. We are willing to alter parts of our organization to meet their requirements and specifications, leading to yet another satisfied and loyal customer.

STAFF NEWS

Kim Jørgensen, our most experienced screw flight manufacturer, is celebrating his 40th! anniversary in August. We look forward to celebrating Kim when we return from vacation. Kim was hired on August 18, 1983, by the former owner of BEMA. He was told never to start work on a Monday, as that would just get him fired, which is why he started on August 18, which was, in fact, a Tuesday. Kim makes an average of 200 flights per day, which means that he has made no less than 1,600,000 flights over the 40 years he’s worked for BEMA – that’s quite a lot!

NEW APPRENTICES

We are dedicated to bringing new, young people into our exciting profession! This year, we have signed four new blacksmith apprentices. Two have already started work, and the other two will start in August. We are excited to give them a solid foundation for their future careers.

In addition, we have two apprentices who will complete their training in July this year, and two more in 2024 and 2025.

It takes four years to become a qualified blacksmith. You have to complete a diverse and varied program involving theory, apprenticeships and schooling.

HAVE A GREAT SUMMER, EVERYONE

Everyone at BEMA would like to wish you a great summer and a wonderful vacation when the time comes. The period leading up to the holidays is often particularly busy as everything needs to be in order, but it’s all the more satisfying to be able to relax and enjoy some time off with family and friends.

We will be closed during weeks 29 and 30 (from Friday 14.07 to Monday 31.07).

If you need wear parts or anything else before the holidays, we will be taking and processing orders until Monday 10.07.

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as