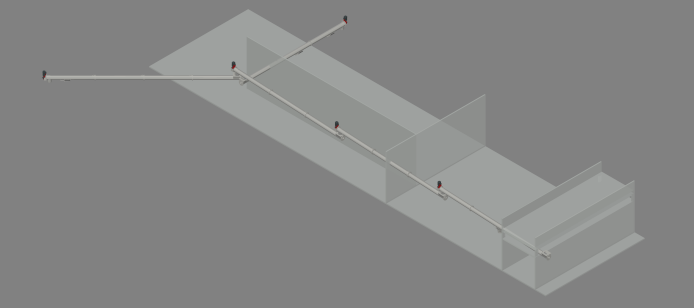

Tube conveyors horizontal for flake ice – 34813

34813

Tube conveyors horizontal for flake ice – 34813

5 pcs. stainless steel tube conveyors – Ø300 – for transportation of flake ice.

Screw conveyors for flake ice transport are most often manufactured in stainless steel.

What is the main design considerations of flake ice conveyors?

- Flake ice is easy to transport in tubular conveyors. The material friction between the steel house and the material is low. This means that you can use gear boxes with relative high speed – up to app. 100 RPM

- It is an acceptable solution to use intermediate bearings in the tube conveyors, and you can make them in a total length to app. 15 meter

- Screw conveyor transport has a low power consumption compared to a blower solution. The screw conveyor transport is gentle towards the flake ice compared to a blower solution

- The wear on a tube conveyor for flake ice almost nothing. The screw conveyor can last for decades, and you might only need to change a bearing after many years of use

- A screw conveyor system for flake ice often have many outlets to different places in the production. BEMA has experience to manufacture suitable gate valves suitable for flake ice

- All welding in a tube conveyor shall be 100% since flake ice is considered as food stuff medium

Screw conveyors for flake ice are often used to distribute the ice from a centralized flake ice machine to the different places in the production facilities. BEMA has experience to deliver screw conveyors and intermediate bins in order to fulfill demand of flake ice on the destination point.

What are the key points for the horizontal screw conveyors for this application?

- Manufacutred with intermidite bearings to ensure a self carried screw rotor

- Bolted together in sections, both house and rotors for easy mounting on-site

- Delivered with special designed gate valves for flake ice

- The tube conveyors are manufactured in modules and easy to adapt to every location needed flake ice conveyors

BEMA has made the design in cooperation with the end customer.

Tube conveyors horizontal for flake ice – 34813

- Type of screw conveyors: Tube conveyors

- Material: 1.4301/AISI-304

- Execution: All welding 100%

- Surface treatment: Acid pickled after welding

- Gear boxes: Delivered in a corrosion protective paint system

| Industry | Food industry |

|---|---|

| Applied steel in product | Stainless steel |

| Product type | Screw conveyor |

| Surface treatment | Stainless steel – acid pickled |

| House | Pipe |

Related solutions

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as