Trough screw conveyors for flake ice – 28318

Trough screw conveyors for flake ice – 28318

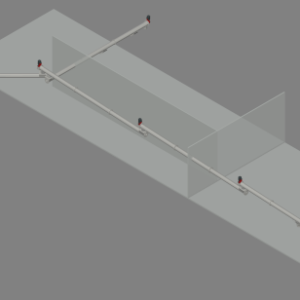

Trough screw conveyors for flake ice manufactured as a complete trasnportation line in a fish factory. The screw conveyores pick up the flake ice from an ice storage and transport the flake ice to diffrent delivering points inside the fish factor.

The transported material is flake ice which is relative easy to transport in a screw conveyor.

What to look for when you work with flake ice

- If possible avoid using intermediate if you have space enough

- When designing gate valve be sure that they can operate during a temperature below 0 degree Celcius

- Note that flake ice is typical in contact with food material – ensure that the screw conveyors comply with EC-1935/2004 (the food directive)

- Use insulation of the screw conveyor trough to reduce melting of the flake ice during transport

- Make it easy to open the lids of the screw conveyor for easy cleaning

- Ensure that all welding are 100% to obey the requirements in EC-1935/2004

In this project BEMA has delivered a complete project of 10 complete screw coveyors.

What has been delivered in the project?

- Measurement on-site before design of the screw conveyors

- Design of 10 screw conveyors after measuring on the location

- Manufacturing of 10 trough screw conveyors for flake ice in BEMA

- Performed FAT on all screw conveyors after manufacturing

- Delivering of the 10 screw conveyors to the final destination

- Participated in installation and trial run of the 10 screw conveyors

The delivery of the screw conveyors is an example of the following tasks BEMA can offer as a total delivery or parts of it:

- Measurement on-site by assistance of a 3D scanner tool

- Design of screw conveyors and related components

- Manufacturing of screw conveyors

- Installation on site followed by a trial run

Trough screw conveyors for flake ice – 28318

- Length: 4000-6000 mm.

- Diameter: Ø300

- Matierial: Manufactured in stainless steel 1.4301 without intermediate bearings

- All screw conveyors have self carried inner tube

- Exectution:

- Welded 100%

- Acid pickled after welding

- The screw conveyores are insulated with 50 mm. mineral wool and covered afterwards

- The screw conveyor lids delivered with hinges for easy opening during cleaning and maintenance

- Delivered with pnumatic gate valves to the delivery points inside the factory

- Delivered including brackets for easy installation to the roof

- The complete project delivered in one shipment and BEMA has assisted for the installation

| Product type | Screw conveyor |

|---|---|

| Industry | Food industry, Process industry |

| Transported material | Bulk material |

| Applied steel in product | Stainless steel |

| Surface treatment | Stainless steel – acid pickled |

Related solutions

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as