Screw coneyor for ash transport with built in water tank – 24371

Screw coneyor for ash transport with built in water tank – 24371

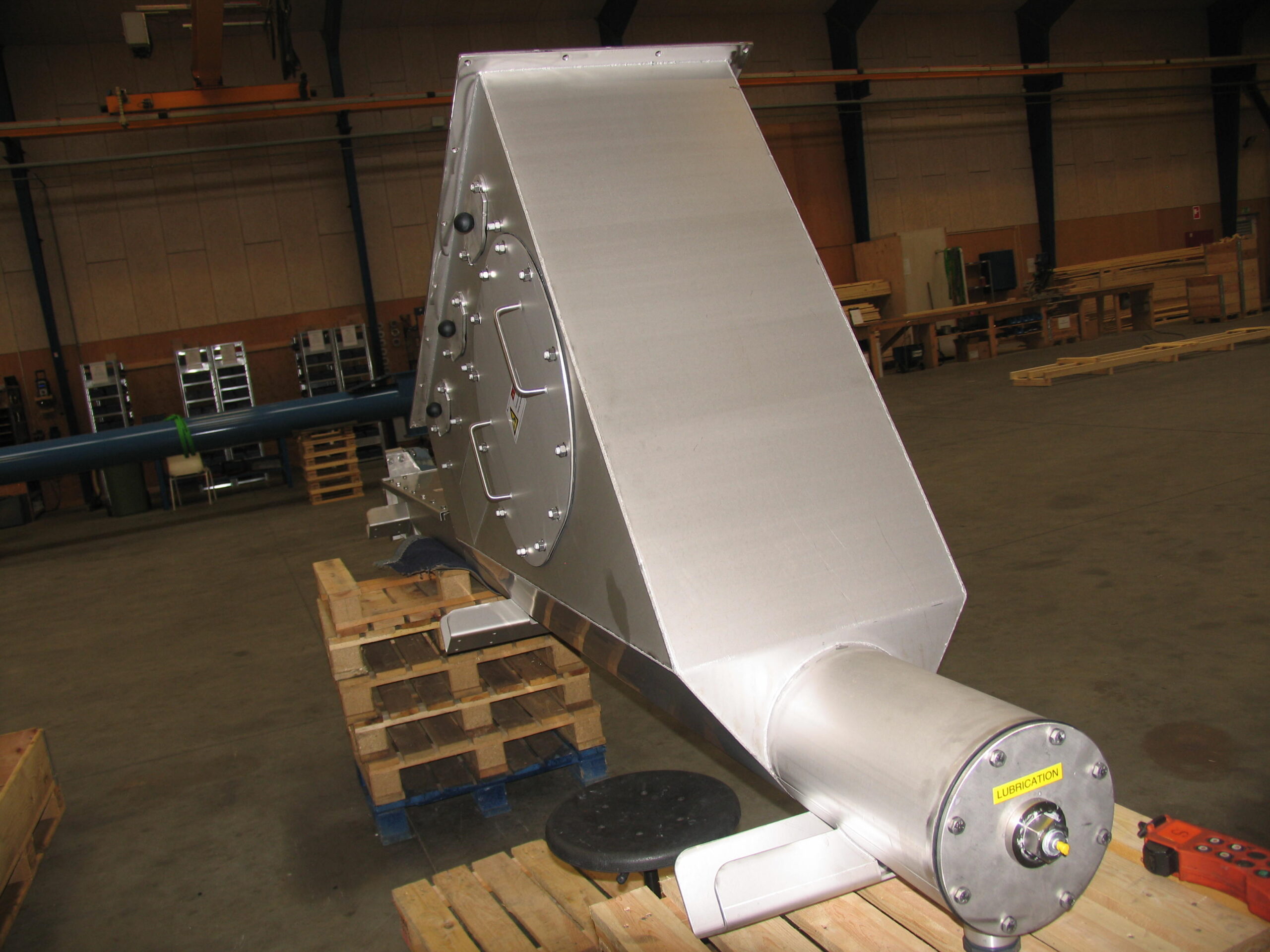

This is a process machine which receives final ash fragments from the burner in a power plant. The screw conveyor for ash transport is placed in the bottom under the last ash take-out from the burner.

The ash fells into a water tank. In the bottom of the water tank, there is a screw conveyor that lifts up the humidified ash and ensure that the water is drained out from it, before it fells out into the container.

The water level is regulated with 2 sensors placed in different hight (low level/high level). The water is connected to a solonoid valve that receives the signal from the sensors. It is a very plain and stable solution, which ensure a constant water level in the tank.

The machine is manufactured as a complete system and checked for water tightness before shipping to the customer.

BEMA has designed the complete solution and assisted the final client under the installation proces to ensure that it fulfills the idea of drainage and ash-transport as a complete solution.

The screw conveyor solution is a much more stable and plain solution compared to a chain conveyor or similar solution. The only moving part is the screw rotor which has a water tight bearing in the bottom. For easy maintenance, the bearing is replaceable from the outside.

Screw coneyor for ash transport with built in water tank – 24371

- Manufactured in 1.4401/AISI-316 stainless steel

- All weldings 100% and acid pickled after welding

- The bottom bearing is designed for use in water

- Supplied with a gear box on the top with a low speed that ensures drainage of the humidified ash

| Industry | Power plants |

|---|---|

| House | Trough |

| Surface treatment | Stainless steel – acid pickled |

| Product type | Screw conveyor, Silo / bin |

| Transported material | Ash |

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as