Horizontal screw conveyors for cutting material – 36562

Horizontal screw conveyors for cutting material – 36562

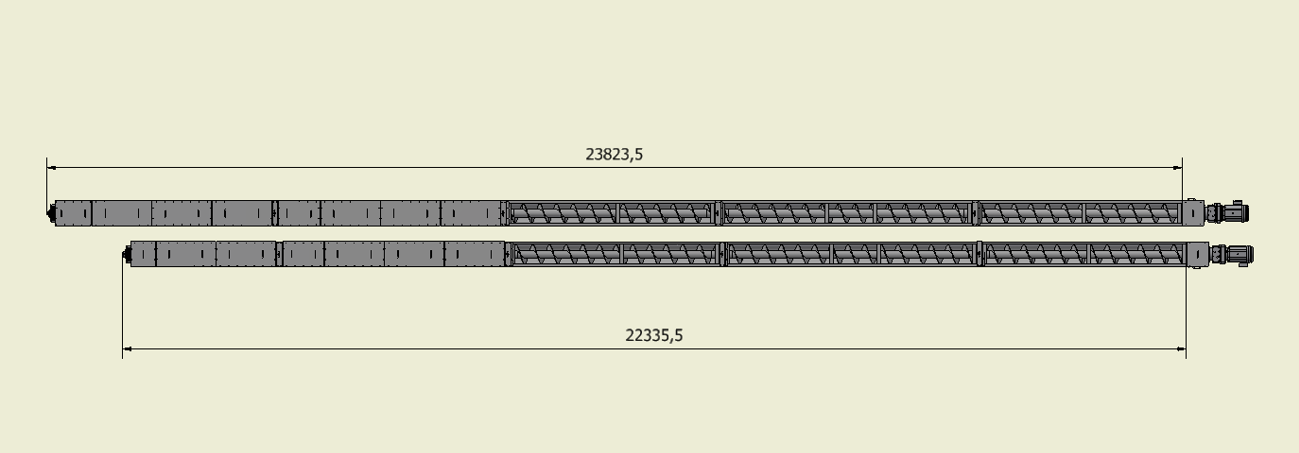

Horizontal screw conveyors for cutting material manufactured for an off-shore application. BEMA has designed and manufactured 2 pcs. horizontal screw conveyors to transport cutting material from the shaker to an outlet system on a drill rig. The 2 horizontal screw conveyors have a length of app. 23 meter.

What is the key points for screw conveyors for off-shore?

- Specific design rules and related off-shore specification must be obeyed

- Design has to meet a rough environment off-shore

- Placement of the horizontal screw conveyors are often in ATEX zones

- Documentation requirements for the screw conveyors are comprehensive

In the actual application the ATEX demands for electrical equipments in the ATEX zone is: II2G Ex eb IIB T3 GB

ATEX: This refers to the European Union directive for equipment used in potentially explosive atmospheres.

II: Equipment group. In this case, it’s suitable for all above-ground explosive environments.

2G: Device category for gas. It indicates that the equipment is suitable for areas 1 and 2.

Ex eb: Type of protection. “eb” stands for increased safety.

IIB: Gas group. It specifies the type of gas (in this case, IIB).

T3: Temperature class. The equipment can operate safely up to a maximum surface temperature of 200°C.

GB: Geographical area. It’s relevant for the European Union and EFTA countries.

During the design phase, BEMA has clarified the ATEX requirements in cooperation with the customer, and ensured that all used electrical equipment confirms to the specifcation.

Follow this link for another ATEX approved solution

Other key design elements for the cutting screw conveyors

- The screw rotors are supplied with intermediate bearings to ensure that they are self carried

- A chain coupling between the gear box and the screw rotor is applied for easier maintenance on-site

- Support cribs delivered with the screw conveyors for smooth and fast installation off-shore

See another example of a cutting screw conveyor here

What documentation level can be deliver for our screw conveyors?

- EC-conformity declaration

- ATEX approval documentation for our screw conveyors and used components

- Machine drawings with part lists

- User manuals and other relevant technical manuals

- Material certificates – we have incoporated a material control system in our quality system

- Welding towards own WPQR’s

- Welders certificates

- FAT test reports

- Test certificates on demanded tests during the manufacturing

In BEMA we have an experienced design department that support our prodution department with drawings and descriptions to ensure that we can meet the requirement towards the screw conveyors.

Horizontal screw conveyors for cutting material – 36562

- Type: Trough screw conveyor

- Diameter: Ø400

- Length: 22228 mm and 23337 mm

- Material:

- Housing and supporting elements: 1.4404/AISI-316l

- Screw rotors: Carbon steel 1.0570/S-355

- Execution: All welding 100 %, stainless steel parts acid pickled after welding

- Intermediate bearings for supporting the screw rotors over the full lenght

- Chain coupling between gear box and screw rotor for easy maintenance on-site

- Outside electrical equipment ATEX approved for gas application: II2G Ex eb IIB T3 GB

| Applied steel in product | Carbon steel, Hardox plate, Stainless steel |

|---|---|

| House | Trough |

| Product type | Screw conveyor |

| Surface treatment | Stainless steel – acid pickled |

Related solutions

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as