Dosing screw conveyor with feeder screw – 14631

-

Dosing screw conveyor with feeder screw – 14631

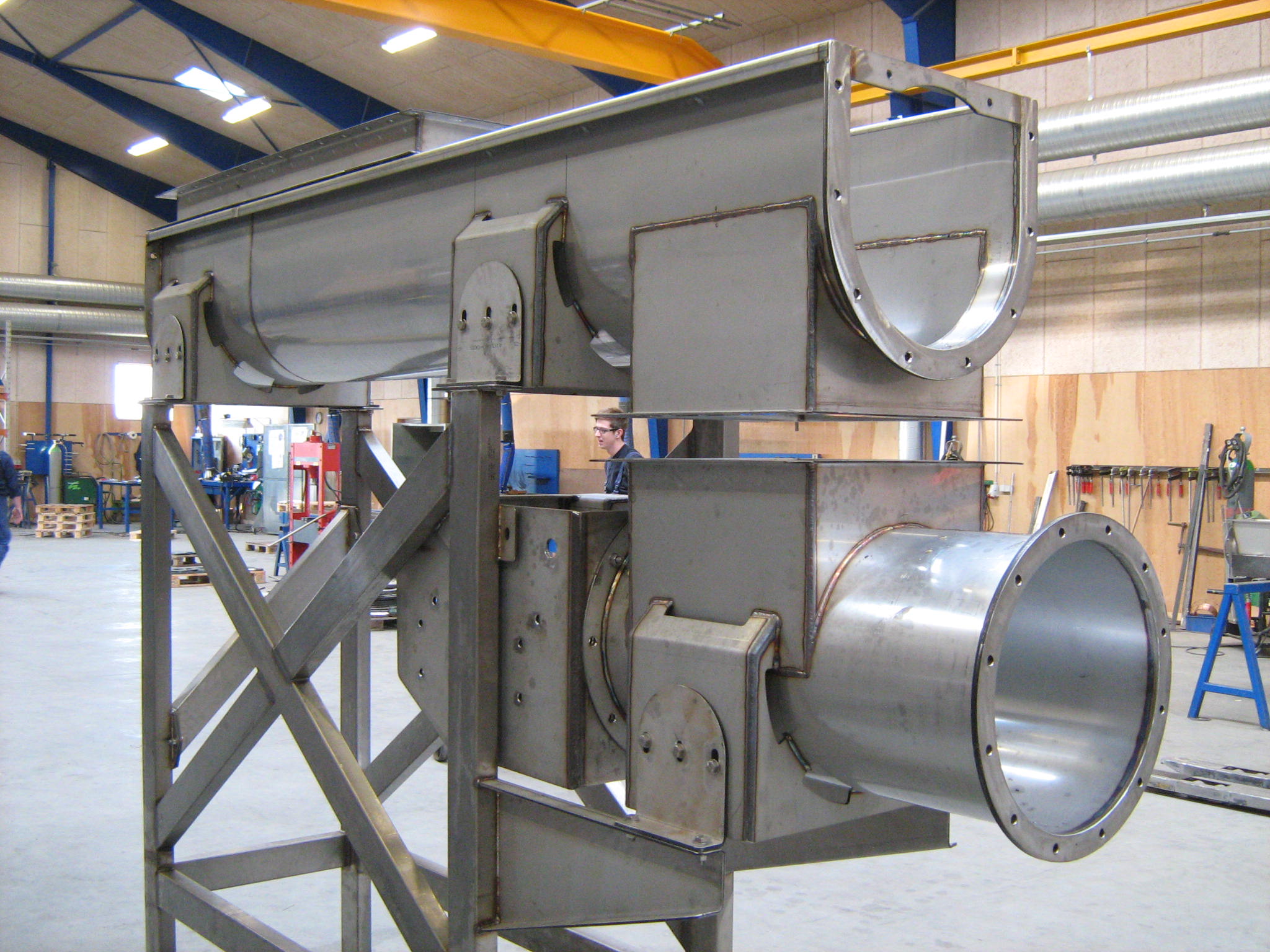

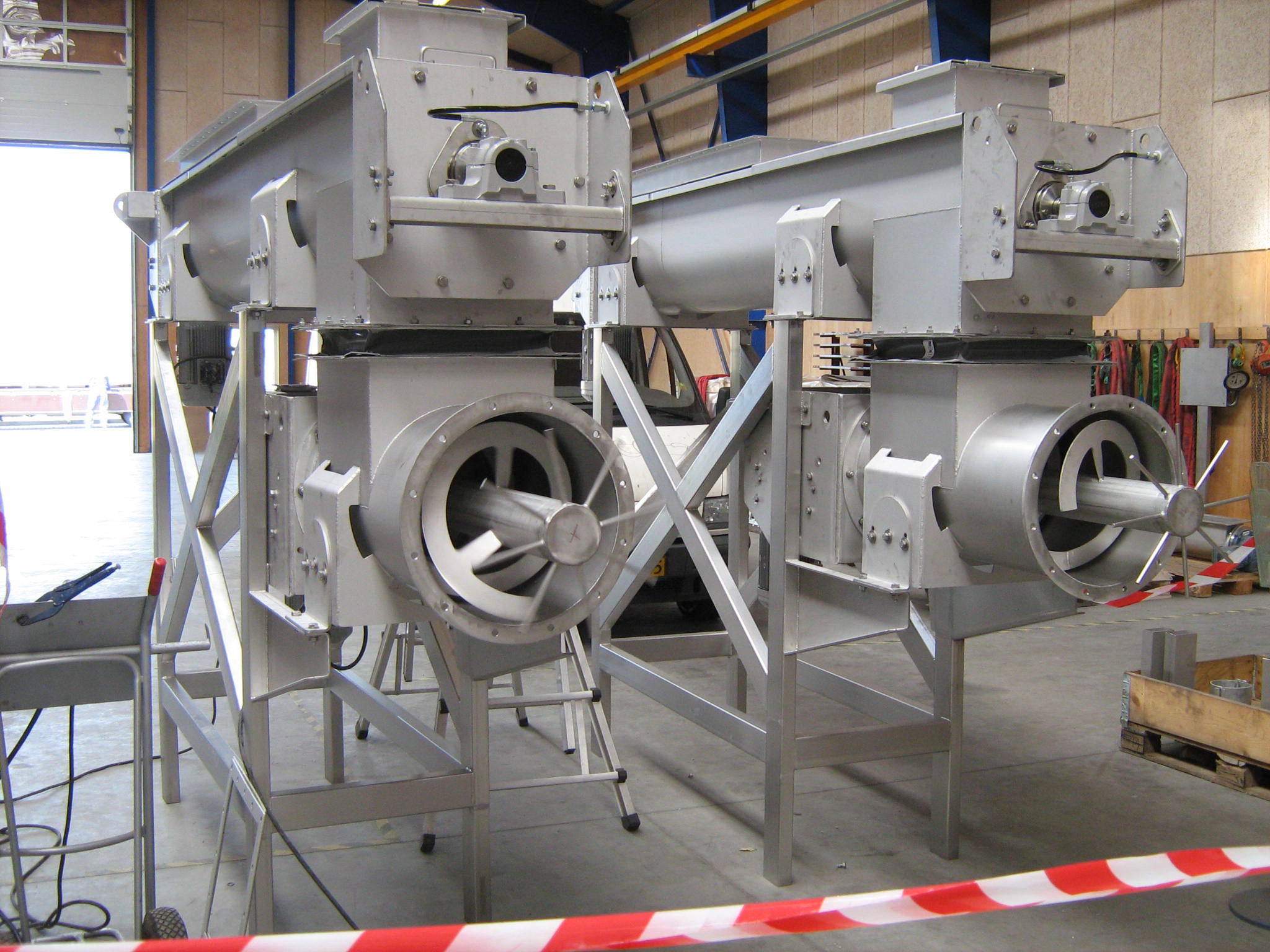

The system contains 2 equally systems of one dosing screw conveyor followed by a feeder screw.

How is the dosings screw conveyor designed in combination with the feeder screw?

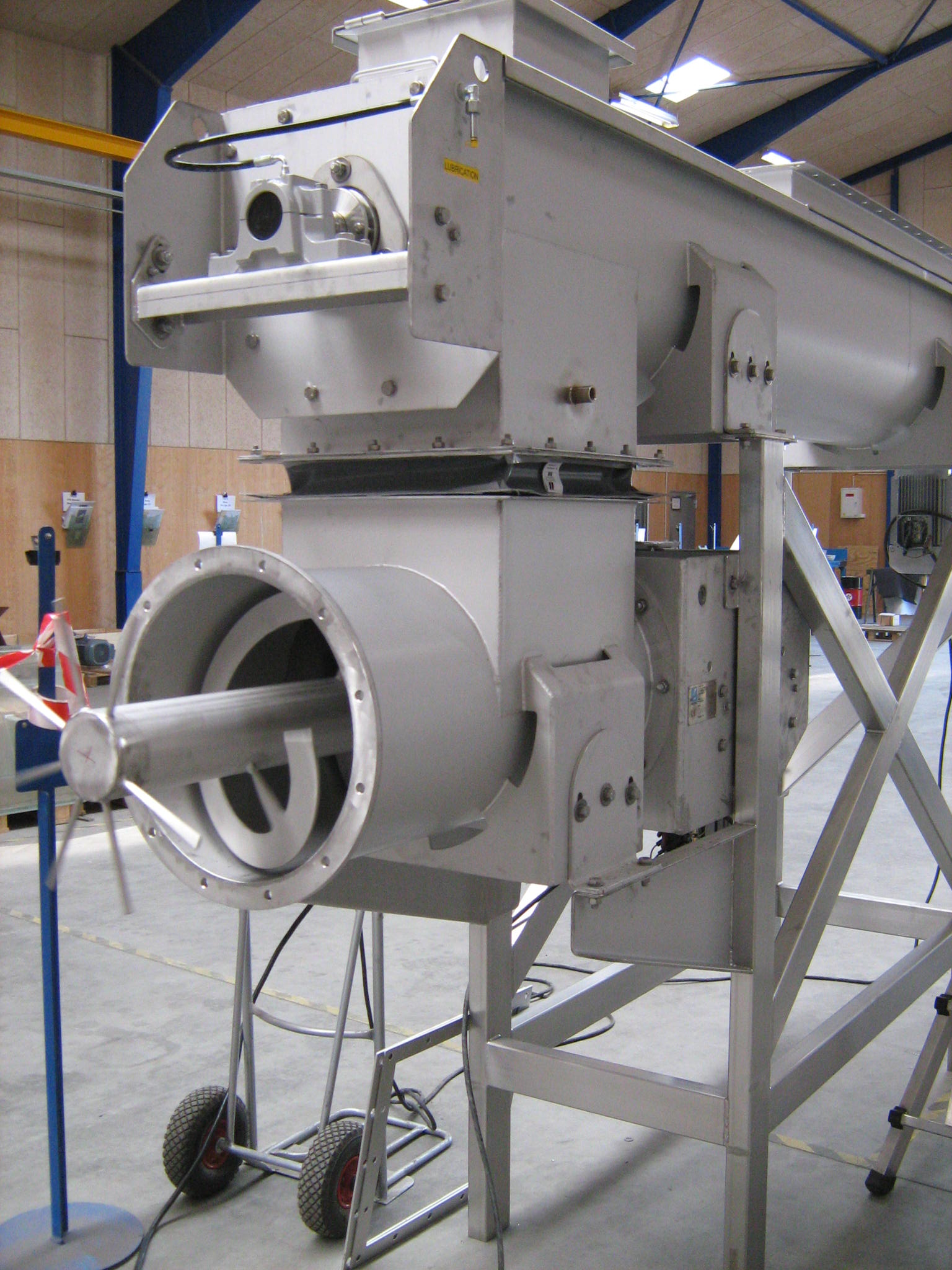

- The Dosing screw is placed on the top of the system

- Under the dosing screw conveyor, the mixing screw is receiving the material

- The feeder screw feed a reactor tower in a chemical process

The very important keypoint of this solution is that the 2 functions are separated. During the many years of the operation, the customer has changed the pitch of the dosing screw conveyor and made some extra mixing modification on the feeder screw. These changes have been made independantly of each other. This a key point to remember in all screw conveyor design and technology – do not combine functions in a dosing screw conveyor.

See an example of a combined dosing screw which went wrong

If you are in a process designing dosing screw conveyors with other functions – mixing, cooling, chopping or whatever kindly contact BEMA. We have many years of experience, and we are willing to help you in getting the system design in a way, where you can optimize and improve your solution over the year. We consider our machines as long living products that are continously improved in your process plant.

-

Dosing screw conveyor with feeder screw – 14631

- Used material: The complete screw conveyor system is manufactured in 1.4401/AISI-316

- Execution: All welding 100% and acid pickled after manufacturing

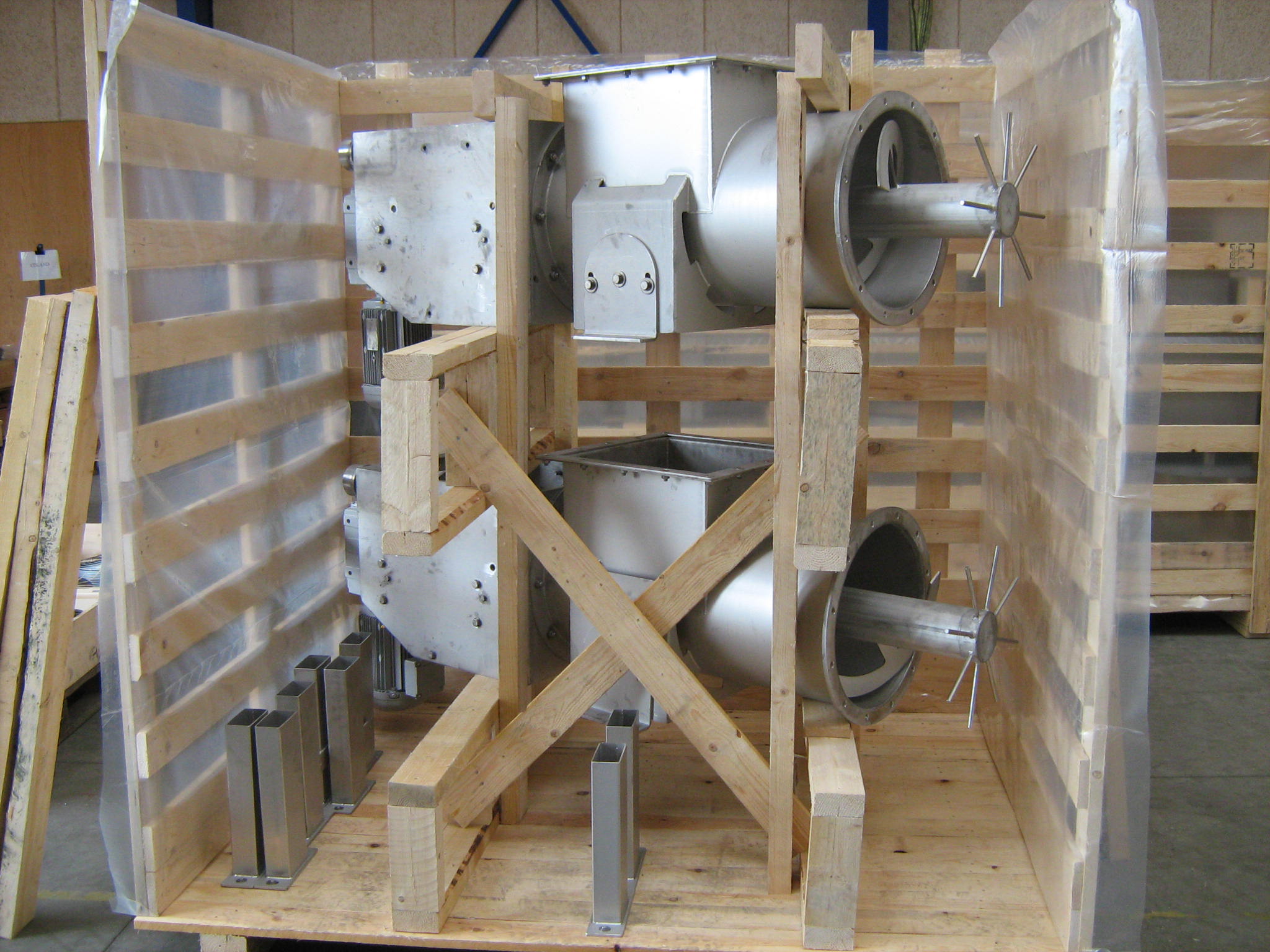

- Documentation: Drawings, manuals, data sheets for wear parts and material certificates delivered to the client as part of the delivery

- Packed in wooden frames and covered in plastic, ready for shipment from our factory

-

Product type Process equipment, Screw conveyor

Industry Process industry

Transported material Bulk material, Powder

Applied steel in product Stainless steel

Surface treatment Stainless steel – acid pickled

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as