Dosing screw conveyor – double with bin ATEX approved – 36058

-

Dosing screw conveyor – double with bin ATEX approved – 36058

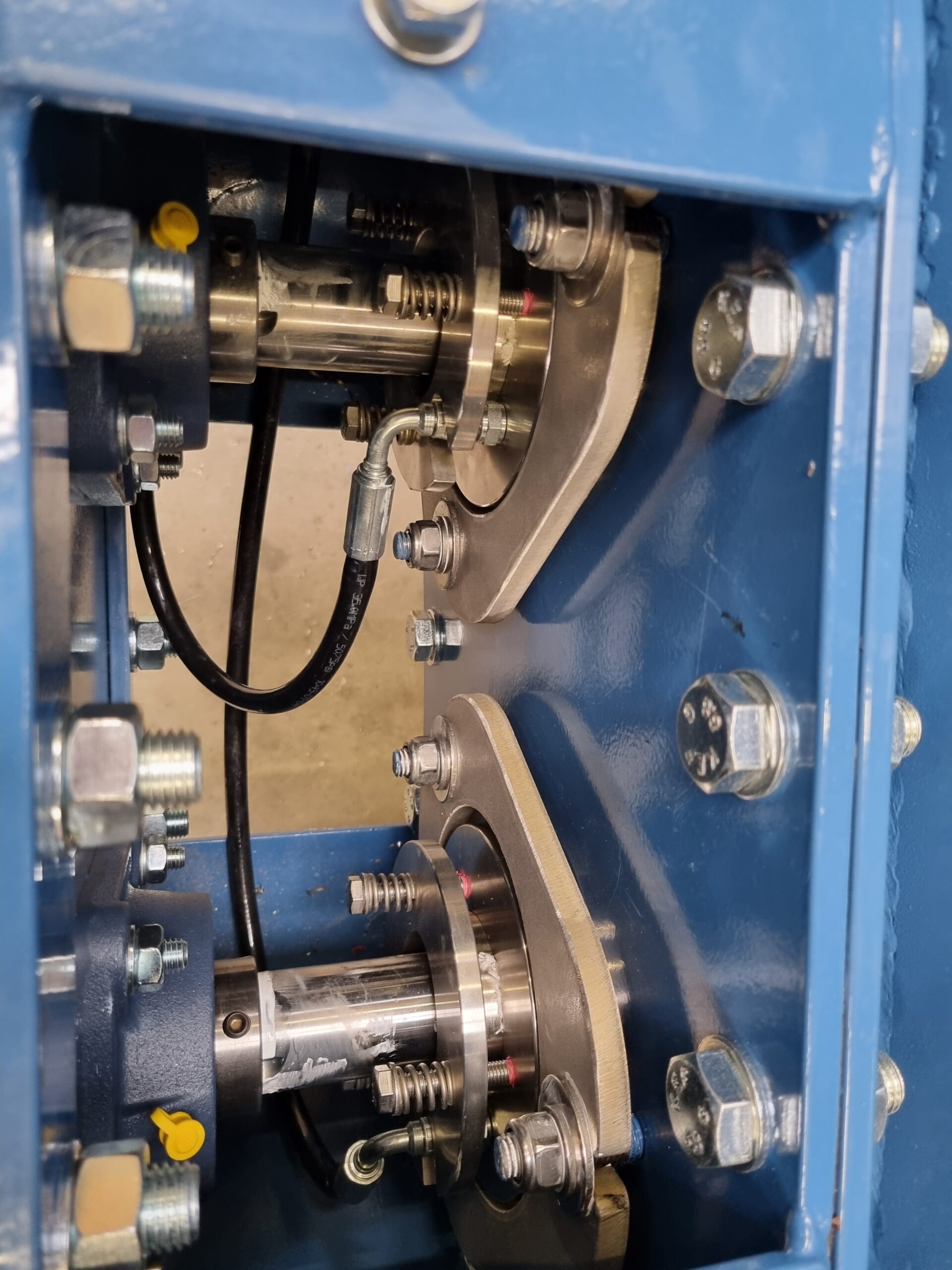

Two bins with double screws in the bottom. The screw rotors are 100% filled and act as dosing screws for the material taken out from the bin. The transported material are additives to a foundry process.

Due to dust in the production area, the solution is designed for ATEX zone 21 inside the bin and ATEX zone 22 outside the machine. BEMA has incorporated this in the CE-documentation. In the design BEMA has assured that the tip speed of the screw auger is belov 1 m/sec.

When a screw rotor is completly filled it can be used for dosing by changing the speed of the auger. Dosing by using augers are used in many places in the industry:

- Additives to foundry processes like this application

- Powder feeding in the food industry

- Biofuel feeding right before the burner in power plants

A dosing screw is very often an economical solution in comparison with batch fillings in combination with weight sells. Dosing screws just require a knowledge of density in the material whereafter you can control the massflow just by changing the speed of the screw rotor. The engineers in BEMA can design the screw auger in cooperation with your process engineers and assist you in selecting the correct diameter/pitch ratios to get an optimal stable solution.

-

Dosing screw conveyor – double with bin ATEX approved – 36058

- Manufactured in carbon steel and painted to RAL 5007 according to customer specifications

- Screw flights manufactured in HARDOX 450 to increase life time due to abbrasive material

- The screw rotors are manufactured with self carried inner tubes. There is no contact between the screw auger and the house of the bin. This increases the life time, and ensures the application with respect to ATEX requirements

- Volume of Buffer silos approx 1,5 m3

- ATEX compliance inside for zone 21, outside for zone 22

-

Applied steel in product Carbon steel, Hardox plate

House Bin, Pipe

Industry Process industry

Product type Screw conveyor, Silo / bin

Surface treatment Carbon steel – painted

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as