Shaftless screw conveyor inclined tube conveyor – 34260

Shaftless screw conveyor inclined tube conveyor – 34260

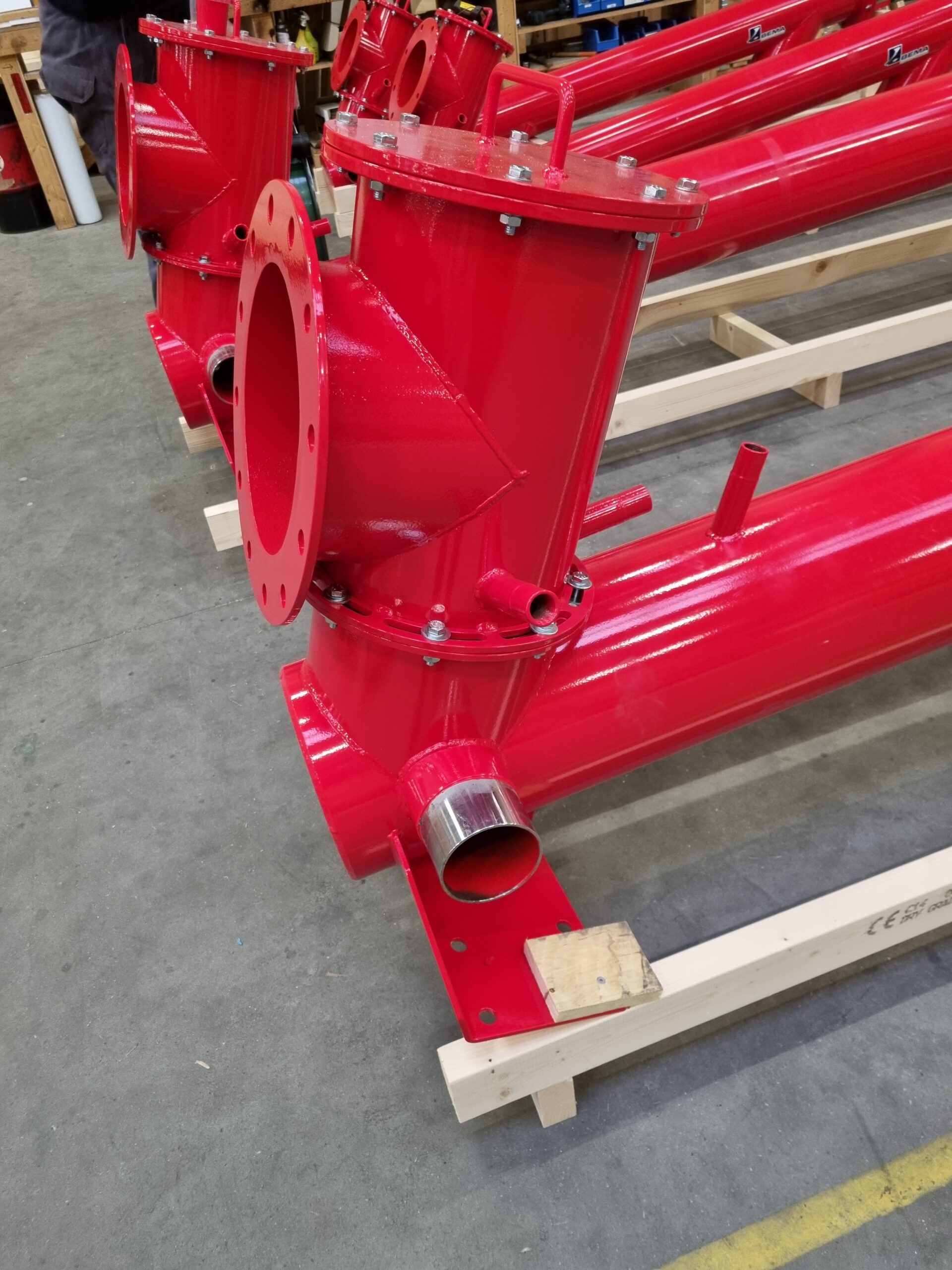

4 pcs. shaftless screw conveyor manufactured for removing rock waste in a biogas plant. The minor rock parts are removed from the process, and the shaftless tube conveyor transport them and dump it into a small container.

Shaftless screw conveyors have certain advantages to be noted:

- They are non-clogging and are specially suitable for sticky material

- In this case they are also good to handle rock waste within the size of the screw rotor

- For longer conveyors you avoid to think about intermediate bearings

When using shaftless screw conveyors, the speed of the screw rotor has to be relatively low – typically below 30 RPM. If the transport requires a high volume flow in combination with a speed above 50 RPM, the shaftless screw conveyor is not a stable solution. In such case you shall use a conventional screw conveyor with an inner pipe.

Features of these shaftless screw conveyors

- They are made with precise connection point, to fit together with exsisting equipment on site

- They have been tested over a long time period to verify that they are suitable for rock waste

BEMA has production capability to manufacture shaftless screw conveyors as well as conventional screw conveyors with an inner pipe. Our engineers and designers can assist you in selecting the most optimal solution for your application.

See another example of a shaftless tube conveyor here

What is the most commonly used material for shaftless screw conveyors?

- Carbon steel – 1.0570/S-355

- Stainless steel – 1.4301/1.4401 AISI-304/AISI-316

- Hardox steel

BEMA has developed efficient method for handling Hardox and other hardened steel types for manufacturing screw flights:

- Cylindridal flight segments

- Shaftless screw flights

If you have abrasive materials to be transported these type of steel will increase the lifte time of the application.

BEMA can always assist you with advise when you evaluate which type of screw flight you want to use for your application – shaftless type or a conventional screw rotor with flight segments welded to an inner pipe.

Shaftless screw conveyor inclined tube conveyor – 34260

- Diameter: Ø191 and Ø240

- Length: 4500-5000 mm.

- House manufactured in carbon steel

- Screw flights in Hardox-450

- Coupling between screw shaft and the gear box

- Special connection points, with flange dimension to fit exsisting equipment

- Painted according to customer specified color

| Applied steel in product | Carbon steel |

|---|---|

| House | Pipe |

| Industry | Waste handling |

| Product type | Screw conveyor |

| Surface treatment | Carbon steel – painted |

| Transported material | Biomass |

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as