Shaftless screw conveyor for sludge – 24029

Shaftless screw conveyor for sludge – 24029

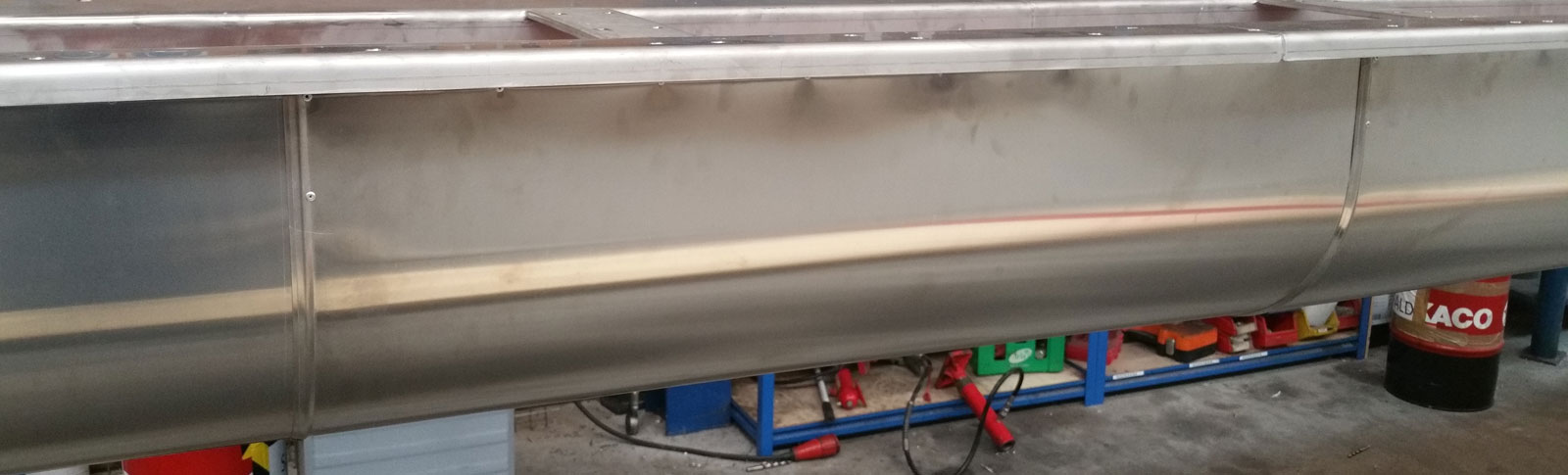

Shaftless screw conveyor designed for transportation of sludge. This shaftless screw conveyor is installed outside, and actions have to be taken to avoid freezing of the material during winter time. In this case, heat tracing have been applied to the screw conveyor housing. The screw conveyor is finally insulated with 50 mm. insulation and covered with an aluminium enclosure.

What is the advantages of using a shaftless screw conveyor?

- The schaftless screw conveyor is ideal for sticky materials such as sludge

- You avoid using intermediate bearings

See another BEMA shaftless screw conveyor solution here

One important thing to note is that a shaftless screw conveyor is not self carried. It is always in contact with the bottom of the trough. No matter how you design the trough, the design will per definition increase wear. If the material can be transported in a conventional screw conveyor, you should always be looking for this solution.

Which types of applications can use a shaftless screw conveyor?

- All transport inside a sewage plant

- Waste handling in a slaughterhouse which often is sticky

- Certain transport solutions in the food industry – meat processing, bread factories, food processes with sticky substances etc.

- Draining processes in the process industry – see this application

Shaftless screw rotors are manufactured in the following main types of material

- Carbon steel such as 1.0570/S-355

- Stainless steel such as 1.4301 or 1.4401/AISI-304 or AISI-316

- Hardox steel

When manufactured in Hardox steel the shaftless screw rotor is manufactured from flight segments welded together. This solution is relevant if the material is abbrasive in combination with being sticky.

BEMA has experience in designing and manufacturing shaftless screw conveyors in different types of materials and for various applications. We can assist you in the design phase to obtain the best possible solution for your specific application.

Shaftless screw conveyor for sludge – 24029

- Length: 13000 mm

- Diameter: Ø230

- Material:

- Housing: 1.4301/AISI-304

- Screw rotor: Carbon steel

- Lining: PEHD-1000

- The screw conveyor is heat traced to avoid freezing of the material during winter time

- Insulation in 50 mm. mineral wool and finalised with an aluminium jacket

- Insultation to ensure protection of the heat tracing

| Product type | Screw conveyor |

|---|---|

| Industry | Waste handling |

| Applied steel in product | Carbon steel, Stainless steel |

| Surface treatment | Stainless steel – acid pickled |

| Transported material | Biomass, Bulk material |

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as