ACTA shredder for recycling of insulation wool – 31374

ACTA shredder for recycling of insulation wool – 31374

ACTA shredder for recycling of insulation wool – 31374, is a machine designed to meet the increasingly demand for more global recycling, set by governments. This particular model is customized for the wool insulation industry, enabling the shredding of entire batts from the manufacturer’s production line in case of defects, as well as processing cut-offs or reclaimed insulation materials from construction-, demolition sites, and general recycling facilities.

Why recycle insulation materials?

Recycling insulation materials is crucial because European governments are increasingly holding material manufacturers accountable for reusing and recycling their products effectively. This approach gives a win-win situation, allowing governments to cut down on CO2 emissions and waste in general, but also enable manufacturers to reduce their own CO2 footprint and preserve raw materials. By using recycled materials back into their production lines, manufacturers not only save on raw materials but also extend the life cycles of these materials by using them repeatedly for as long as possible.

This leads to a more efficient circular economy for the manufacturer, resulting in a more robust business. Over time, this can also lead to better pricing for consumers, as savings on raw materials are likely to reduce the total production costs.

How does it work?

An ACTA shredder efficiently processes insulation material, breaking it down into smaller pieces, allowing a better sorting process of foreign objects such as nails, silver foils, wrapping, and wood pieces.The insulation can then be transported back to the furnace and remelted back into the production lines again.

The unique design of the ACTA shredder prevents bridge building, and even lighter wool material will be pulled down by the ACTA screws and pushed out through the output holes and knives. The ACTA screws will tear apart even the most compact bales of insulation wool, creating a “kneading” effect inside the ACTA. This “kneading” effect is essential to prepare the wool for easier remelting in the furnace.

Customization of an ACTA

The desired output fragment sizes can be adjusted by customizing the rotating knives, which are very easy to change on an ACTA shredder – it only takes 4 bolts for each screw.

An ACTA is a highly versatile machine that can be customized to fit perfectly into your production. This specific build has a large list of upgrades and improvements to meet the high demands of our customer – a short list includes:

- Outlet screw conveyor with closed protection cover for easy transport of output

- Protection cover for motor/gear (mounted on-site) – will protect againt impact from trucks or falling debris of material

- Extended filler hopper for increased loading capacity together with a lower loading hight from ground point

- Hardface metal welded on each of the 6 screws for increased protection for weardown

- Reliable gear and motor setup – frequency driver controlled

- Complete control cabinets, with touch panel and PLC from Siemens and frequency drivers Integrated

- Everything integrated with exsisting equipment on site, for complete setup

- Painted in the customer’s specified color

An ACTA is built to last, with a gear setup, customized control panels, and hard facing metal on the screws, results in machinery that can operate 24/7 if needed, with nothing more required than feeding it the material, that you wish to be crushed or shredded.

Please feel free to reach out to us if you are curious to hear more about an ACTA solution for your project. – you are also welcome to look at some of the other ACTA solutions we have made, at our website of by following this link her

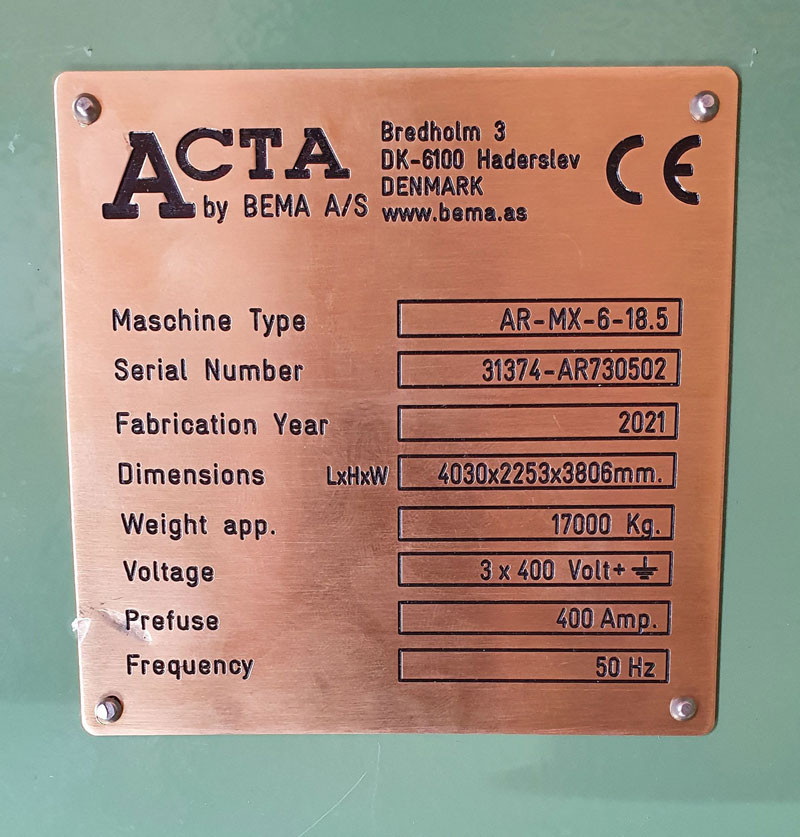

| Weight | 17.000 kg |

| Hopper inlet dim. | 4250x2000mm. |

| Hopper volume. approx. | 10 m3 |

| Outlet capacity

All outlet capacities are approximated and depends on working conditions and type of material to be processed. Please contact sales for ACTA for more exact information. |

6-15 ton/hour |

| Screw speed | Approx. 12 rpm |

| Motor power | 6 x 18,5 kW |

| Electrical conn. | 3×400 V – 50 Hz |

| Prefuse (App.) | 400 Amp |

| House | Bin |

|---|---|

| Transported material | Insulation, Minerals |

| Industry | Insulation, Recycling, Waste handling |

| Surface treatment | Carbon steel – painted |

| Product type | ACTA crusher |

Related solutions

Related products

-

ACTA 2-screw crusher for ceiling tiles- 33924

Read more -

ACTA crusher for gypsum recycling – 33281

Read more -

ACTA shredder for recycling of industrial PU panels – 32717

Read more -

30424 ACTA 4-screw Crusher – Reverse filler hopper + full control cabinet and additional equipment

Read more -

31257 ACTA 6-screw Crusher with reverse hopper

Read more

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as