Screw rotors

Screw rotors can be made to convey all materials whether liquid, granulate, or powder, from fly ash to meat products. BEMA produces all types of screw rotors in all steel grades.

BEMA screw rotors are produced entirely to customer specifications. The smallest screw rotor diameter produced to date is Ø35 mm and the largest Ø4000 mm.

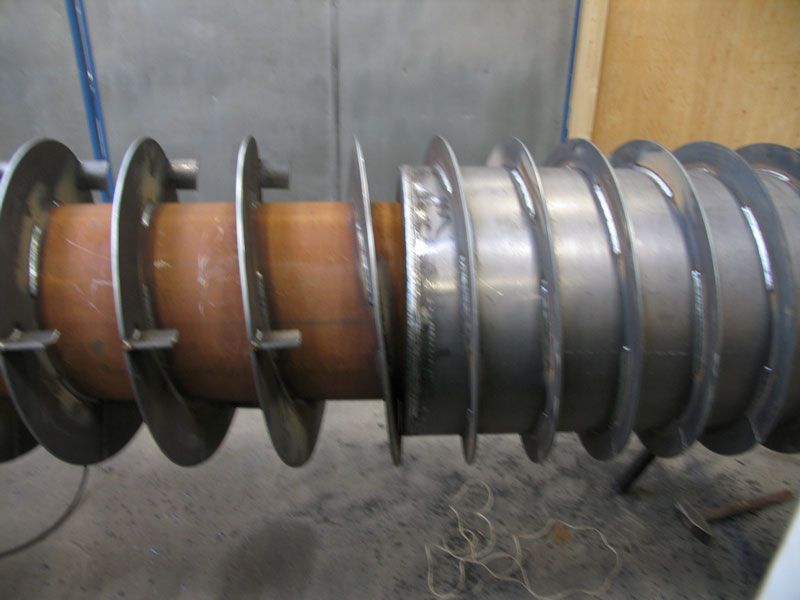

Conical

Screw rotors

The screw filling is often adjusted with the aid of conical arrangements.

Conical augers for fluidisable media

Conical augers are used for fluidisable media but also for pressing media as they pass through the screw auger – now functioning as a press screw auger. This would be done if e.g. a medium needed to be dewatered, fruit juice separated from fruit and berries, or wastewater from sewage sludge, or similar. Carbon steel screw augers are used when large capacity, extra wearability, and extended operations are a must – with no specific requirements for food hygiene standards.

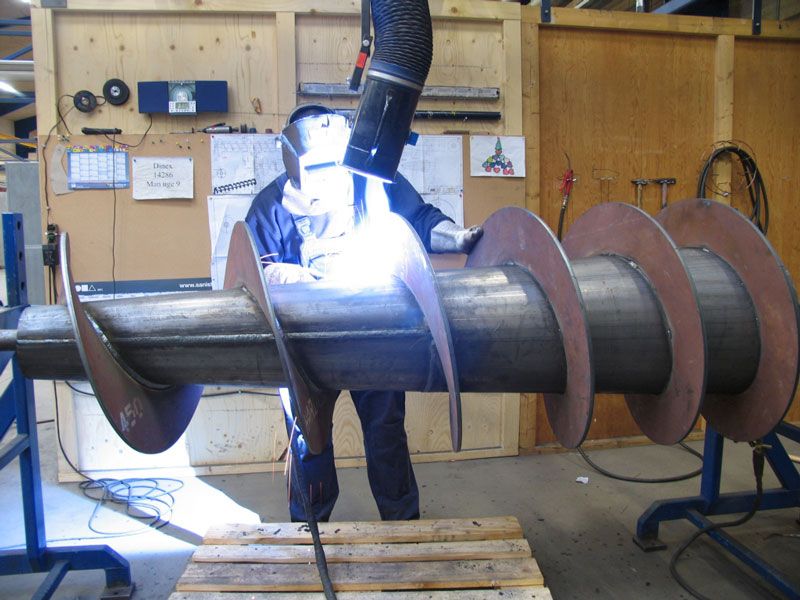

Wear plates

Screw rotors

Various coatings in either wear plate flights or hard metal welding-on are available for strongly wearing media.

Please contact the sales department for more information on the advantages.

Wear augers

BEMA offers screw conveyor augers with wear flights. Screw conveyor wear flights are used when the auger is required to convey highly abrasive materials, including raw materials such as cement, lime, fly ash from CHP plants and abrasive granulates. Wear flights prolong the auger’s lifetime and can easily be replaced, as they are welded on separately and are thus replaceable like any other spare part. Wear flights are produced in HARDOX 450 or HARDOX 500 steel grade.

Shaftless

Screw rotors

Shaftless flights’ uses include: Greasy and sticky media such as in cleaning systems and similar.

Why pressed axleless flights and not rolled? Unlike rolled flights, shaftless pressed flights have the advantage that they have the same material thickness in the inner and outer diameters, giving a better durability and strength.

Shaftless screw rotors for viscous materials

A shaftless screw rotor is mainly used for viscous and oily or sticky media. This could be a foodstuff factory, a wastewater treatment plant, or the food industry. Shaftless screw rotors where the flights rotate inside the screw conveyor housing are also used as e.g. a screw feed stoker to transport wooden pellets, bulk material, and other types of granulates. This type is flexible and resilient within certain tolerances.

Outer cutting

Screw rotors

Exterior slotting is often used where the rotor must chop, mill or ream a particular medium.

Mincing auger for process work

A screw auger for mincing is used in process equipment where materials require a degree of processing on its way through the screw auger. BEMA has supplied screw augers for mincing to the food industry and other industrial sectors. A padle screw auger with e.g. helical or helicoid notches are used to stir a medium on its way through the auger. A helical auger has notches on the inner side of the screw flights close to the shaft. Notches can also be made on the outside of the screw flights facing the conveyor housing, and the auger will then mince and break up the medium.

Contact

Contact Lars Rask Lambertsen and find out more about BEMA’s solutions for screw rotors.

Screw augers for a wide range of end uses

For seventy-five years, BEMA A/S has specialised in industrial process equipment of the highest quality, including the production of screw augers for all kinds of end uses. An auger or screw auger is the core in a number of different processes which involve the conveying of materials. Either as part of a production process or in other contexts where a medium has to be conveyed from one place to another. Furthermore, a screw auger allows a series of processes to be carried out, so that, in addition to moving the material, it can also be processed. Screw rotors are capable of both moving and processing a medium. To give an example, BEMA solutions involve different augers for mincing, augers for kneading, augers for boiling, and augers for mixing, respectively. Different augers for different tasks will enhance the efficient handling and rationalisation of production processes in process equipment by means of screw conveyor transport.

What exactly is a screw auger?

A screw auger or rotor consists of a core on which are mounted various types of screw conveyor flights. In this way, augers or rotors are constructed for specific applications in customers’ process equipment. Augers are also an essential part of BEMA’s line of ACTA bale openers and crushers/shredders and they are therefore a central part of our product range.

Two of BEMA’s skilled staff inspect a custom-built auger before being installed at the customer.

Augers for many different sectors

BEMA produces augers used widely in a variety of industrial sectors. The design of the auger core combined with the specific flights define the type of auger or rotor and its specific application.

BEMA supplies screw augers for many industrial sectors: screw augers for the food industry, augers for agriculture, and primary industry, and augers to convey various kinds of powders and granulates in the paint industry, plastics industry, and production industry, respectively, as well as other types of enterprises. BEMA augers are e.g. used in enterprises within the wind turbine industry, the offshore and bulk industries, the fish-processing industry, as well as the engineering industry.

Moreover, augers are used in a number of public or semi-public enterprises, including combined heat- and power plants (CHP plants), wastewater treatment plants, and utility companies.

Which materials would you typically convey using a screw rotor?

A rotor with a core and flights is designed for a specific application. This could either be simply conveying a medium from one place to another, or perhaps that the rotor is required to perform various additional tasks while the material is passing through. So, depending on their design and construction, rotors are suited to a variety of media and raw materials. Screw rotors are used for transporting, mixing, kneading, or stirring all types of materials in granulate or powder form or in small constituent parts. Rotors can also transport liquidisable materials in various consistencies from watery liquids to thick, viscous ones.

History of the screw auger

In ancient Greece, screw augers were used to conduct water from wells or rivers up to the fields. The method was invented by the Greek scientist Archimedes. The first screw auger was therefore known as the Archimedean screw and the principle is still in use, e.g. in irrigation systems.

A screw auger can be used for all types of materials from water, oil, and other fluidisable materials to granulates and raw materials. Screw augers are widely used in the food industry.

Several different types of augers and rotors

BEMA produces several types of augers and rotors used in all the industrial sectors mentioned above – and probably more. Stainless-steel screw rotors are used specifically in the food industry where high standards are required for hygiene as well as for joints and welded seams. BEMA holds all the necessary certificates and approvals, including ISO certification, to be able to supply stainless-steel screw rotors for the food industry.

Augers as part of a total solution

BEMA offers screw conveyor auger services customised to the specific task the auger is required to perform. Augers with standard flights, large-pitch augers, conical augers, shaftless augers, wear-flight augers, augers with backward-facing flights, augers with inner and outer flight notching, as well as stainless-steel screw augers. The possibilities are endless and, consequently, BEMA offers custom-built solutions.

As a total solution for an enterprise’s process-equipment, screw augers will be close-coupled to the rest of set-up and several augers/screw conveyors run in continuation.

Right-hand or left-hand flights?

Please note whether your auger flights are right- or left-hand. For a new installation, the direction of the screw is immaterial, as you can adjust or reverse the motor to suit your purpose. When reinstalling or replacing an auger, you can check using a simple trick: if the auger flights move in the same direction as those in an ordinary drill bit in a power drill, it is right-hand.

BEMA – consultancy, design, and delivery of anything from component parts to customised solutions

BEMA has been an actor in the field of auger technology for many years. Moreover, our enterprise is financially stable. BEMA has managed to carve out a solid market position with stable growth and a growing profit. BEMA has its own project department with specially trained engineers, designers, and other skilled staff. BEMA is ISO 9001 certified. Download the BEMA ISO 9001 certificate from www.bema.as.

Contact BEMA’ sales department to discuss your needs and get a competitive price for a screw auger. We are always happy to arrange a meeting at BEMA’s or at your location to design a customised solution to match your needs.

BEMA A/S

Bredholm 3

6100 Haderslev

Denmark

CVR: 15525991

Contact

Phone: +45 74 52 16 21

E-mail: info@bema.as